Shining a Light on UV/LED Curing: A Breakthrough Technology in Material Curing

UV/LED curing systems are widely used in various industries, including printing, automotive, electronics, packaging, and woodworking. These systems play a crucial role in the drying, hardening, and curing of materials by utilizing ultraviolet (UV) or light-emitting diode (LED) technology.

UV/LED curing systems consist of a light source, such as UV lamps or LED arrays, and a power supply unit. The light source emits high-intensity UV or visible light, which triggers a photochemical reaction in a special photoinitiator present in the material to be cured. This reaction instantaneously transforms the liquid or semi-solid material into a solid state.

One of the major advantages of UV/LED curing systems is their high speed of operation. Traditional curing methods, such as heat or air drying, can take a long time to complete. UV/LED curing, on the other hand, achieves instant curing, significantly reducing production cycle times. This is particularly beneficial in high-volume manufacturing processes.

UV/LED curing systems also offer exceptional control over the curing process. The intensity and duration of the light emitted can be adjusted to meet specific requirements. This versatility allows manufacturers to ensure consistent quality and achieve precise curing results.

Additionally, UV/LED curing systems are environmentally friendly compared to alternative curing methods. They do not emit harmful volatile organic compounds (VOCs) or generate excessive heat, making them ideal for use in sensitive applications, such as food packaging or medical device manufacturing.

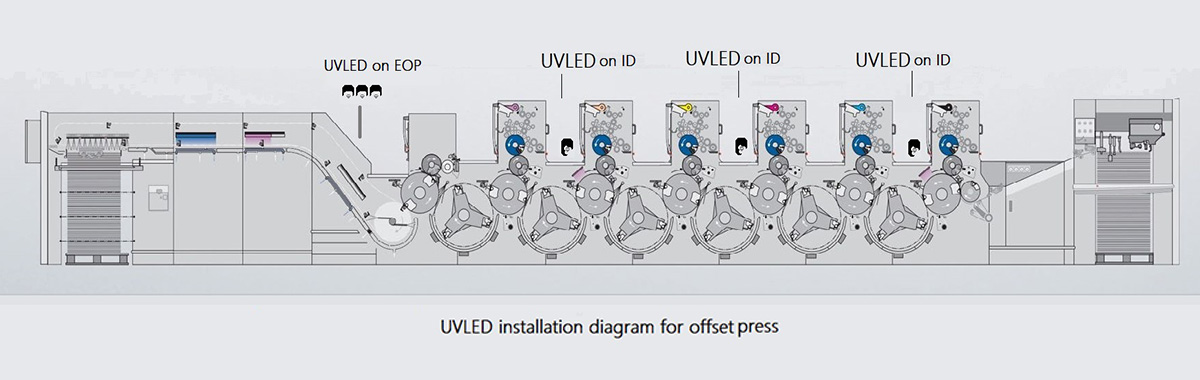

In the printing industry, UV/LED curing systems are widely used for ink drying in offset, flexographic, and digital printing processes. The instant curing ability of UV/LED systems enables faster printing speeds and reduces the risk of smudging or bleeding. Moreover, the use of UV-curable inks eliminates the need for solvents, leading to better print quality and reduced emission of air pollutants.

In the automotive industry, UV/LED curing systems are employed for the fast and efficient drying of paints and coatings. These systems ensure a high-quality finish and eliminate the need for time-consuming thermal drying processes. Moreover, UV/LED-cured coatings exhibit excellent resistance to scratches, chemicals, and weathering, enhancing the durability and longevity of automotive finishes.

In the electronics industry, UV/LED curing systems find application in the production of printed circuit boards (PCBs) and semiconductor devices. UV/LED systems enable rapid curing of adhesives, conformal coatings, and solder masks, ensuring reliable and durable electrical connections. The precise control over the curing process provided by UV/LED systems ensures that sensitive electronic components are not subjected to excessive temperatures or prolonged exposure to heat.

In conclusion, UV/LED curing systems provide numerous advantages across various industries. Their high speed, precise control, environmental friendliness, and superior curing capabilities make them an indispensable tool for achieving efficient production processes and high-quality products.

2025 Jakarta Printing Exhibition in Indonesia(All Print Indonesia)

Vietnam Print Pack 2025 Concludes Successfully: Innovative Water-Cooled UV Systems Lead New Trends in Green Printing

Post exhibition report: Water cooled UV/LED system shines at RoSupack 2025, promoting green and sustainable printing

How does UV technology make your product stand out?

The 11th Beijing International Printing Technology Exhibition Concluded Successfully, Vtech.Co.,Ltd.Guangzhou Achieved Fruitful Results

Vtech water-cooled UV/LED system helps Roland 300 printing machine upgrade efficiency again!

You may also like

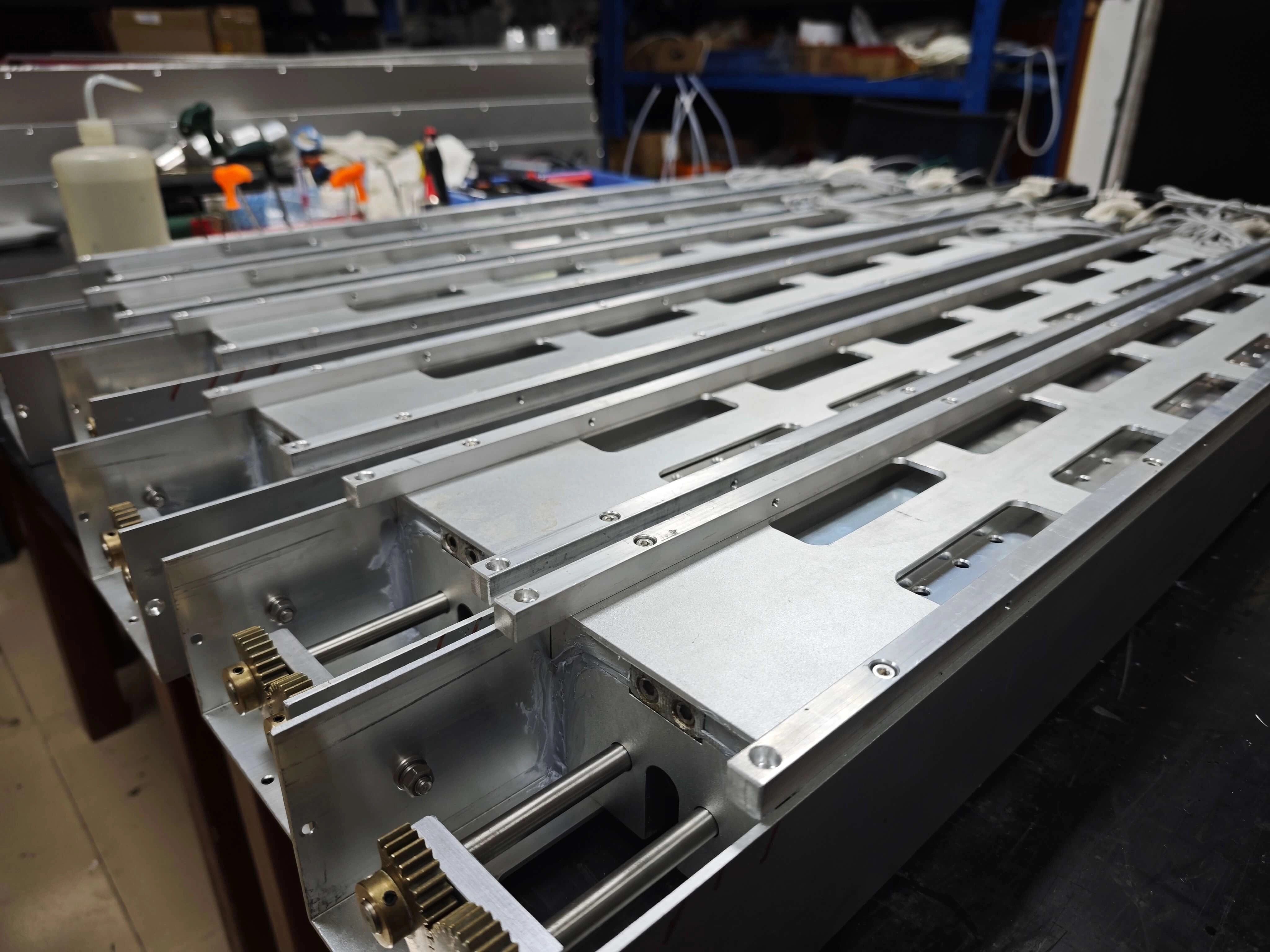

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Get in touch with us

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang