can you uv cure a print too long | WT Guide

Can You UV Cure a Print Too Long? Understanding UV Curing Overexposure WT

UV curing is a precise process. Overexposure can lead to issues like reduced flexibility, yellowing, and even damage to your print. This article clarifies the risks of over-curing and offers solutions.

Understanding UV Curing Time

* The Importance of Precise Timing: UV curing relies on specific energy exposure (mJ/cm²) to fully polymerize the ink. Exceeding the recommended time doesn't necessarily improve curing; it can cause problems. Incorrect exposure can impact adhesion, gloss, and overall print quality.

* Factors Affecting Curing Time: Several factors influence optimal curing time. These include:

* Ink Formulation: Different inks have varying UV sensitivities. Check manufacturer specifications.

* UV Lamp Intensity: Lamp age and output directly affect curing speed. Regular maintenance and calibration are crucial. (Source: )

* Substrate Material: The substrate's absorptivity impacts UV penetration and curing efficiency.

* Film Thickness: Thicker ink layers require longer curing times.

* Signs of Over-Cured Prints:

* Brittleness/Reduced Flexibility: The cured ink becomes excessively hard and prone to cracking.

* Yellowing: Over-exposure can cause yellowing, especially in white or light-colored inks.

* Surface Damage: Excessive UV energy can degrade the ink's surface, resulting in a dull or uneven finish.

* Adhesion Problems: Ironically, over-curing can sometimes *reduce* adhesion in certain applications.

Preventing UV Curing Overexposure

* Follow Manufacturer's Recommendations: Always adhere to the ink and equipment manufacturer's specified curing times and parameters. This is the single most important step.

* Regular Equipment Maintenance: Ensure UV lamps are regularly cleaned and calibrated to maintain consistent output. (Source: )

* Use a UV Meter: A UV radiometer accurately measures the UV energy reaching the print surface, ensuring consistent curing across batches.

* Test Curing Parameters: Always conduct test prints to determine the optimal curing time for your specific ink, substrate, and equipment setup.

* Adjust Conveyor Speed (if applicable): For conveyor belt systems, adjust the speed to ensure sufficient curing time without overexposure.

How does UV technology make your product stand out?

The 11th Beijing International Printing Technology Exhibition Concluded Successfully, Vtech.Co.,Ltd.Guangzhou Achieved Fruitful Results

Vtech water-cooled UV/LED system helps Roland 300 printing machine upgrade efficiency again!

Precision Cooling Solutions Power Global Printing Innovation: Vtech Shines at 2025 South China Printing Expo

Vtech showcases its innovative water-cooled UV/LED solution at the 2025 South China Printing Exhibition, helping to upgrade printing efficiency

How to choose the best UV light for resin

You may also like

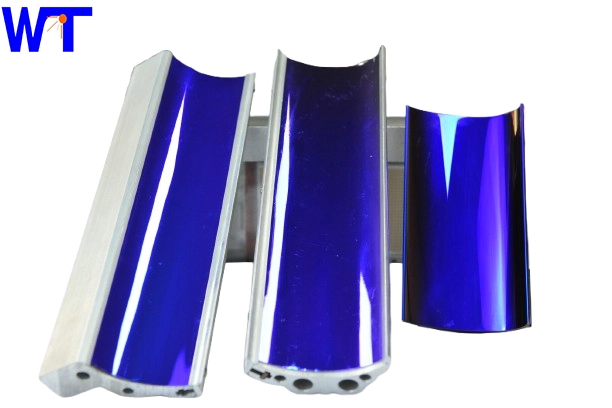

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

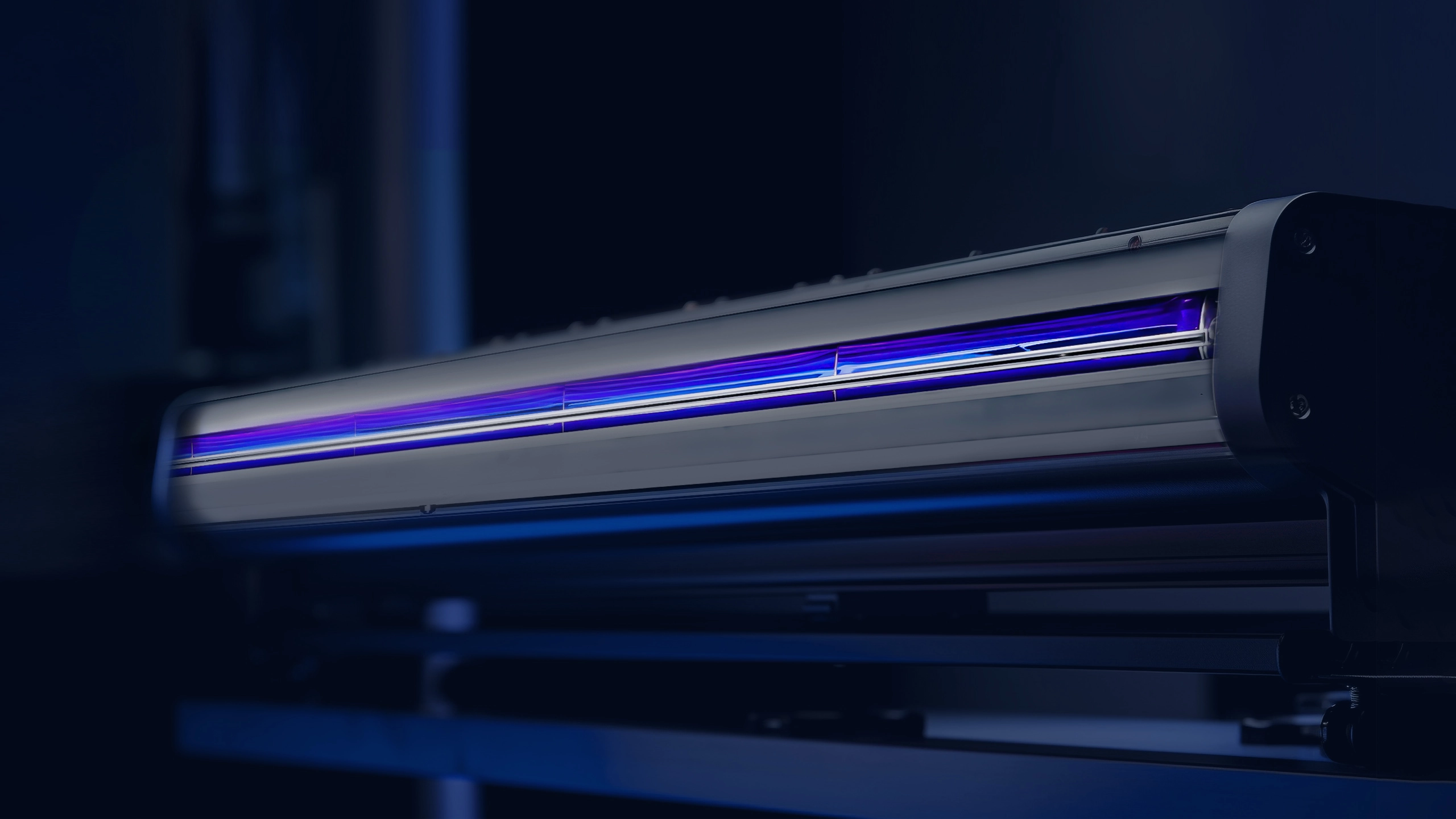

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

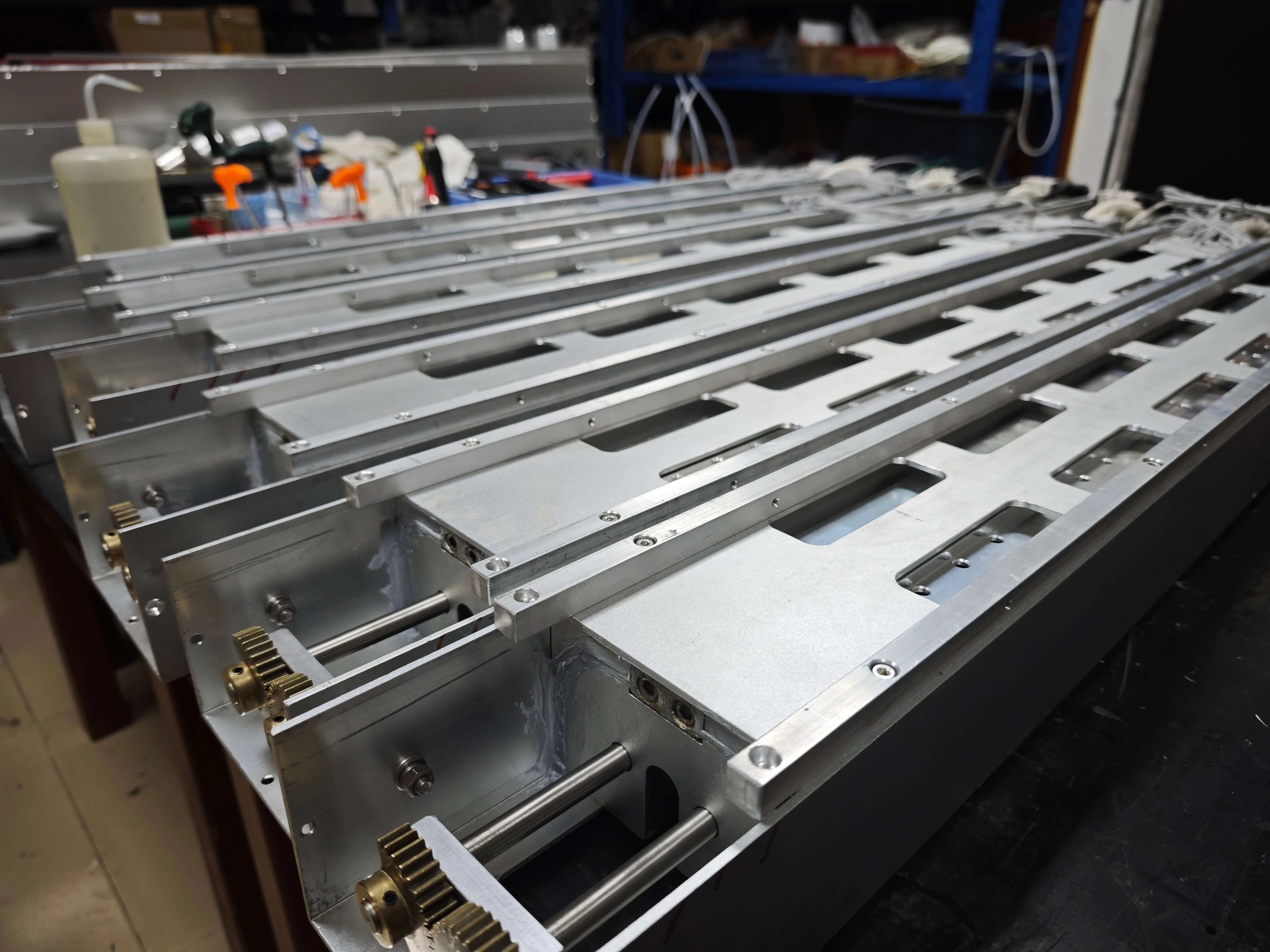

Offset LED pre-press testing machine

Get in touch with us

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang