Revolutionize Your Production with UV Curing Technology

Introducing the revolutionary UV Curing System - the future of fast and efficient curing processes for a wide range of products. UV curing is based on the principle of using ultraviolet light to instantly cure or dry coatings, inks, adhesives, and other materials. This cutting-edge technology offers unmatched benefits compared to traditional curing methods, making it the go-to choice for industries seeking high productivity and impeccable results.

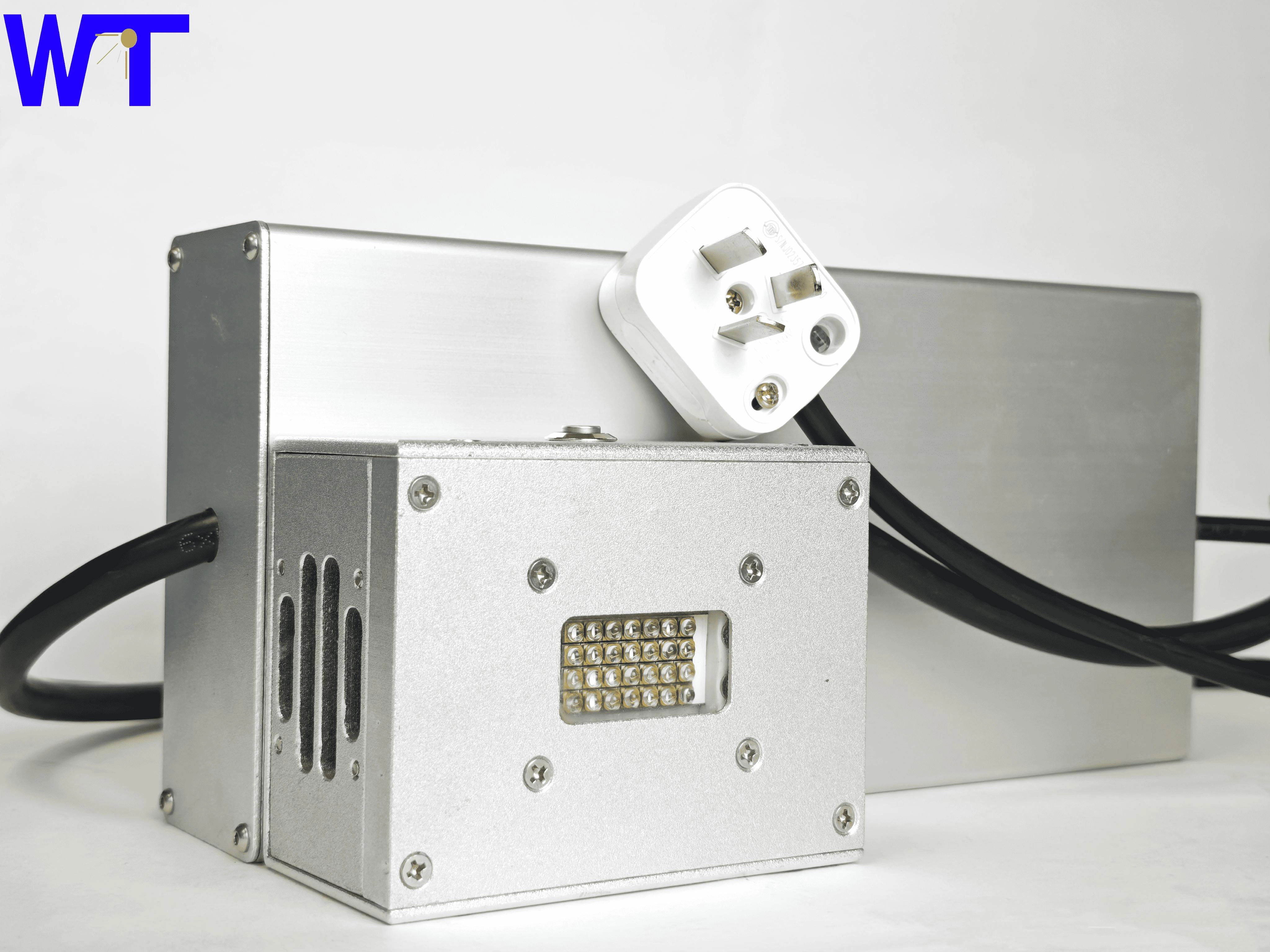

The principle of UV curing revolves around the use of UV light to initiate a photochemical reaction in certain materials, resulting in rapid curing or drying. This process is achieved through the use of UV lamps or LEDs that emit a specific wavelength of light, which triggers the curing mechanism in the targeted material. Unlike thermal curing processes that rely on heat, UV curing operates at ambient temperatures, reducing energy consumption and production time significantly.

One of the key advantages of UV curing is its unmatched speed and efficiency. With curing times ranging from seconds to a few minutes, this technology accelerates the production process, leading to higher throughput and reduced overall production time. Additionally, UV curing results in superior adhesion, scratch resistance, and overall durability of the cured materials, ensuring exceptional quality and long-lasting performance.

Furthermore, UV curing eliminates the need for solvents and other volatile organic compounds (VOCs), making it an environmentally friendly and sustainable solution. This not only contributes to a healthier work environment but also aligns with the growing demand for eco-conscious manufacturing practices. Moreover, the precision and control offered by UV curing systems result in minimal material waste, further optimizing production costs and reducing environmental impact.

In summary, UV curing is a game-changing technology that offers unparalleled speed, efficiency, quality, and sustainability for curing and drying processes across various industries. By harnessing the power of ultraviolet light, this advanced system sets a new standard for productivity and performance, making it an indispensable asset for any modern production facility.

Advantages

The operation interface is simple, the sound and light alarm corresponds to the light source module, and the fault can be quickly determined.

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

LEDs do not produce ozone gas.

We have over 17 years experience in UV curing industry.

Q&A

Why and how do I replace a UV led?

how can we guarantee quality?

Can I use my own PLC and Electric cabinet?

What materials can UV printers print?

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

Offset LED pre-press testing machine

Customized conveyor belt type UV LED curing equipment

Water-cooled LED curing equipment

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang