WT UV LED Spot Curing System: Precision, Speed & Reliability for Modern Manufacturing

Unlock high quality Precision with the WT UV LED Spot Curing System

In today's fast-paced manufacturing world, precision, speed, and reliability are paramount. The WT UV LED Spot Curing System, proudly brought to you by Vtech Co., Ltd., is engineered to meet these demands head-on. Designed for targeted, instant curing of UV-sensitive adhesives, coatings, and inks, our system ensures flawless results with unparalleled efficiency. Whether you're working with delicate components or high-volume production, the WT system delivers consistent, high-quality performance every time.

Why Choose WT UV LED Spot Curing for Your Production?

Optimizing your production process means choosing technology that offers tangible benefits. The WT UV LED Spot Curing System stands out with features that directly translate to enhanced productivity and reduced operational costs:

- Instant & Pinpoint Curing: Say goodbye to long cure times. Our UV LED technology provides immediate curing on demand, precisely where you need it. This dramatically speeds up assembly processes and eliminates bottlenecks.

- Superior Energy Efficiency: LEDs consume significantly less power than traditional UV lamps, leading to substantial energy savings and a lower carbon footprint for your operations.

- Low Heat Output: Protect heat-sensitive materials. The minimal heat generated by LED curing prevents damage, discoloration, and material degradation, ensuring the integrity of your delicate components.

- Extended Lifespan & Reduced Maintenance: WT UV LED systems boast remarkably long operational lives, drastically cutting down on lamp replacement costs and maintenance downtime.

- Consistent & Reliable Results: Achieve uniform curing depths and strengths project after project. Our stable LED output ensures predictable performance, reducing rework and improving product quality.

Applications Where WT UV LED Spot Curing Excels

The versatility of the WT UV LED Spot Curing System makes it an invaluable tool across various high-tech industries:

- Electronics Assembly: Perfect for bonding miniature components, wire tacking, lens positioning, and sealing sensitive circuits.

- Medical Device Manufacturing: Ideal for catheter assembly, needle bonding, and encapsulating sensors, where precise, low-heat curing is critical for biocompatibility.

- Optical & Lens Bonding: Ensures clear, strong bonds for optical fibers, lenses, and sensor assemblies without thermal stress.

- Precision Component Adhesion: Any application requiring accurate, fast curing of small adhesive dots or lines benefits from our system's control.

The Vtech Co., Ltd. Advantage: Expertise You Can Trust

Vtech Co., Ltd., established in 2006, is a recognized leader in UV and LED curing solutions. With numerous industry patents and extensive experience in developing systems for diverse applications, including offset, gravure, flexo printing, and various coatings, we bring unparalleled expertise to every product. Choosing the WT UV LED Spot Curing System means partnering with a company committed to innovation, reliability, and providing efficient production solutions tailored to your needs. Trust Vtech to power your success with cutting-edge curing technology.

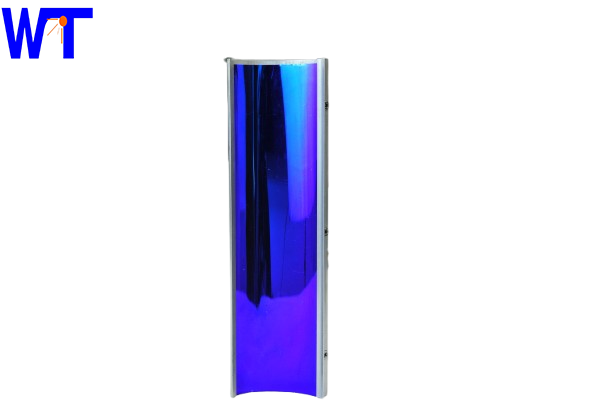

Product Images

Advantages

We are the source factory with professional R&D team and skilled workers.

The light source head adopts a modular design.

With stepless dimming function;

With line disconnection alarm and LED dead point detection alarm function.

Question you may concern

What's the Peak Irradiance do I need?

Why and how do I replace a UV led?

When can I get the quotations?

What is the major advantages of UV LED curing system’s than other UV curing system?

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang