WT UV LED Curing Systems - Efficiency & Quality Redefined

WT UV LED Curing Systems: Superior Performance & Efficiency

Experience the future of curing with WT UV LED Curing Systems, where cutting-edge technology meets unmatched efficiency. Whether you're in the printing, coating, or adhesive application industries, our systems are designed to enhance productivity and provide consistent results with every use.

Practicality and Value:

Our UV LED Curing Systems are engineered for maximum practicality. With a flexible design that fits seamlessly into existing production lines, you can easily integrate it into your workflow. The rapid curing times reduce downtime and accelerate production, ensuring that your operations run smoothly and efficiently.

Energy-Efficient Innovation:

Save significantly on energy costs with our eco-friendly UV LED technology. Unlike traditional curing systems, WT UV LED Curing Systems operate at cooler temperatures, diminishing the risk of heat damage to sensitive substrates. This ensures the longevity of both the machine and the materials, providing you with long-term value.

Enhance Product Quality:

Achieve superior product quality with uniform and reliable curing. Our systems deliver high-intensity UV output with precision, ensuring even coverage and solid bond formation. You’ll appreciate the reduction in product defects and attrition, ly leading to higher customer satisfaction and trust in WT.

User-Friendly Design:

Simplicity meets sophistication in our intuitive interface, allowing for easy operation and minimal training. The adjustable settings and real-time monitoring capabilities empower users to tailor operations and respond promptly to any adjustments needed.

Invest in WT UV LED Curing Systems today and nurture a more efficient, sustainable, and productive manufacturing process. Discover the intersection of technology and care with WT.

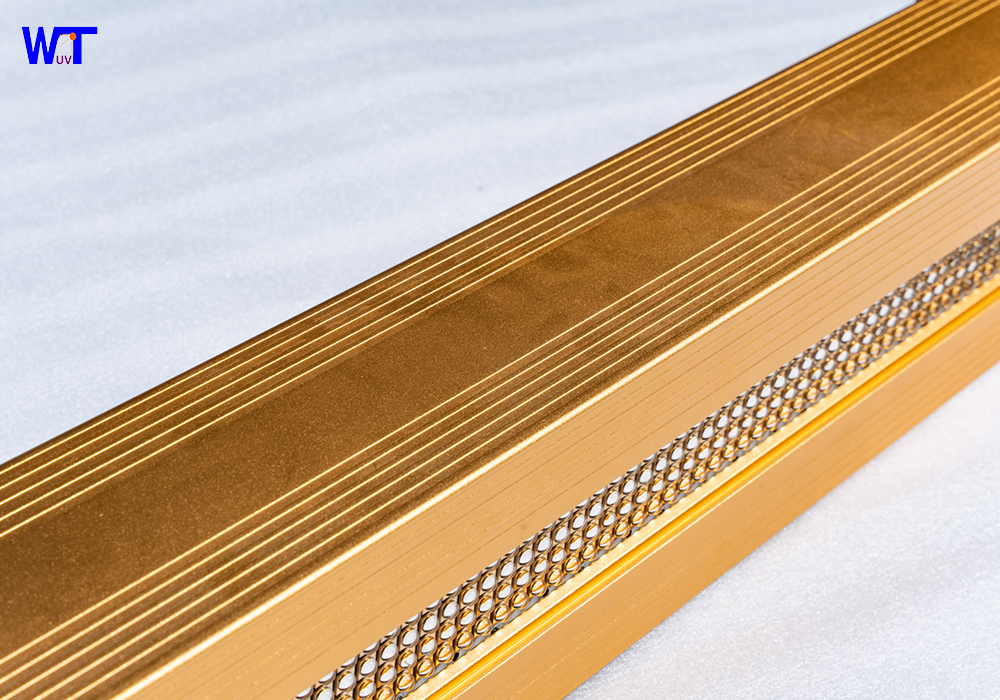

Detailed display

Advantages

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

The light source head adopts a modular design.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

UV energy uniformity ≥ 98%.

FAQ

how can we guarantee quality?

How long will take for mass production?

What's the cooling way?

What should I do when I don’t really know how to setting the printer parameters?

About other questions pls contact me directily.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang