WT UV Curing System for Printing — Reliable LED & Water-Cooled Solutions

Product Overview

WT UV curing system for printing is developed by Vtech Co., Ltd, an experienced manufacturer since 2006. We specialize in water-cooled and LED UV curing systems designed for offset, gravure, flexo, coating lines and silk screen printing. Our patented designs ensure consistent, high-quality curing with reliable performance on modern production lines.

Key Features

- Fast and consistent curing to improve production speed and print durability

- Available in water-cooled and LED configurations to match different press types

- Energy-efficient operation that lowers running costs and reduces heat impact

- Compact, retrofit-friendly design for easy integration into existing lines

- Low maintenance with durable components and simple servicing

Technical Advantages

Our UV curing systems use proven lamp and LED technologies combined with precise cooling control. The water-cooled models manage heat on high-power jobs, while LED units offer instant on/off, longer lamp life, and reduced power consumption. Both options deliver uniform radiation for consistent ink and coating crosslinking, improving adhesion and finish.

Applications

WT systems are suitable for a wide range of printing and finishing needs: offset press, gravure press, flexo press, screen printing, coating lines, and specialty finishing. Whether producing packaging, labels, or commercial print, our curing units help you achieve faster throughput and superior print quality.

Why Choose WT by Vtech

Trusted Experience and Support

Since 2006, Vtech Co., Ltd has developed multiple patents and accumulated extensive industry experience. We offer customized solutions, installation assistance, and responsive after-sales service to ensure your production runs smoothly. Choosing WT means choosing a partner focused on reliable performance and efficient production.

Value for Your Operation

Investing in a WT UV curing system reduces downtime, improves product quality, and lowers energy costs. Our practical designs help operators feel supported and confident, delivering measurable improvements to your printing workflow.

Contact us to find the right WT UV curing system for your printing line and get expert guidance on installation and optimization.

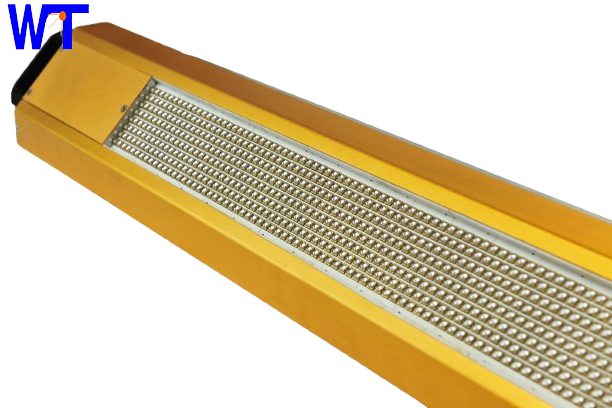

Product Images

Advantages

LEDs do not produce ozone gas.

UV energy uniformity ≥ 98%.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

1. The conveyor speed can adjustment according to the products drying condition;

Q&A

how can we guarantee quality?

Why and how do I replace a UV led?

lf the light intensity is adjustable?

What should I do when I don’t really know how to setting the printer parameters?

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang