WT UV Curing Lamp Systems – Efficiency and Reliability Redefined

Product Description

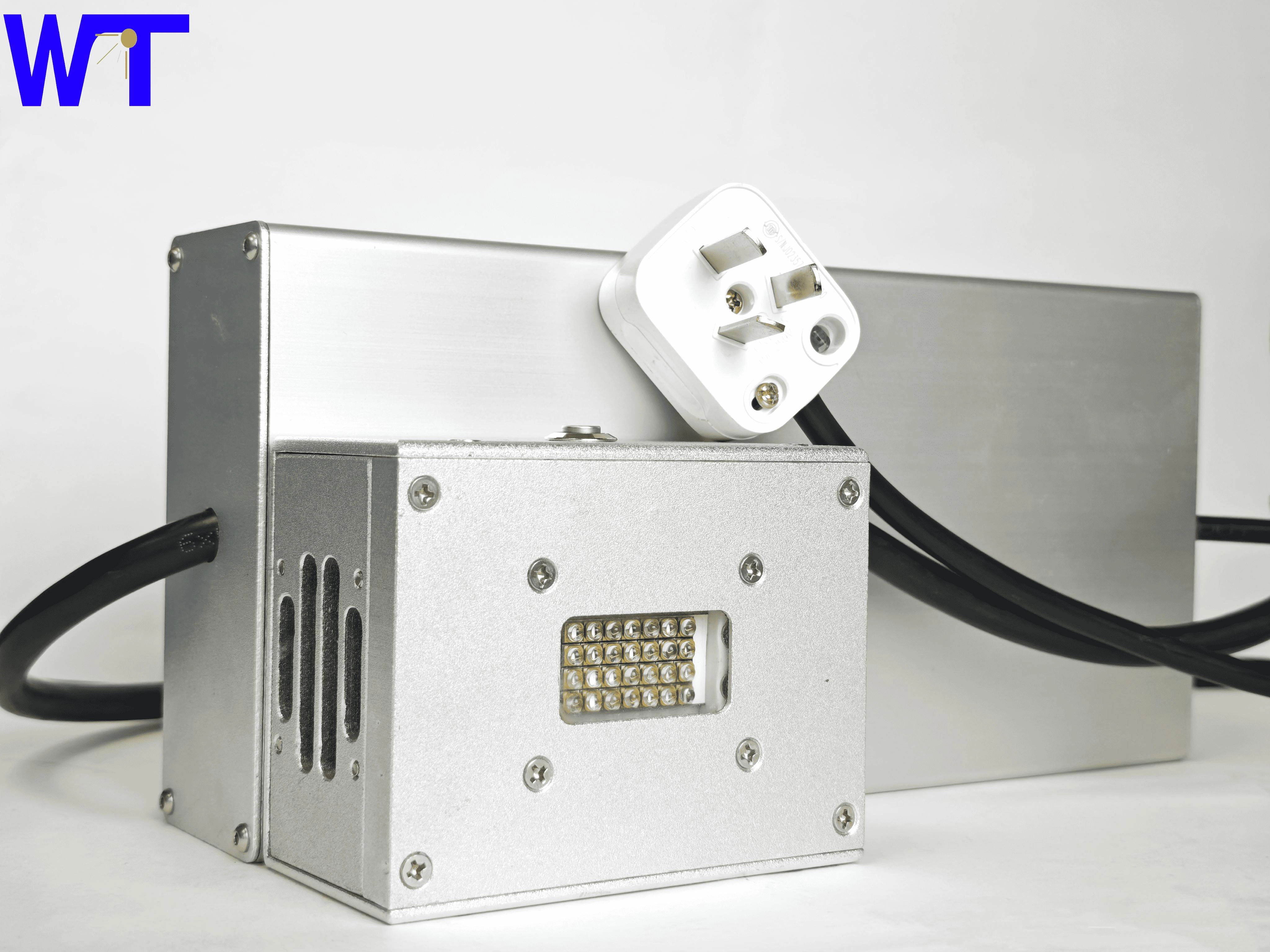

Introducing the WT UV Curing Lamp Systems – the solution for professionals seeking efficiency, reliability, and superior results. Our UV curing systems are meticulously engineered to ensure optimal performance, transforming your curing processes with remarkable speed and uniformity.

Designed with cutting-edge technology, WT UV Curing Lamp Systems provide consistent and high-intensity UV illumination to ensure rapid curing of coatings, adhesives, and inks. These systems are perfect for use across a range of industries, including electronics, automotive, printing, and medical applications. With each use, you will experience shorter curing times, lower energy consumption, and enhanced product quality, setting a new benchmark in industrial curing standards.

Our UV curing lamp systems prioritize user-friendly designs and practical features, allowing for seamless integration into your existing workflows. Equipped with easy-to-navigate controls and robust safety features, the WT systems cater to both novice users and seasoned professionals, ensuring a hassle-free experience every time.

When you choose WT UV Curing Lamp Systems, you're opting for a brand that values quality, efficiency, and user satisfaction. We are committed to providing exceptional customer support and comprehensive service, ensuring your investment continues to deliver excellent value over time.

Elevate your curing processes with the unparalleled performance and reliability of WT UV Curing Lamp Systems, where innovation meets practicality.

Advantages

Light source independent packaging(COB), long service life,energy saving, environ-ment friendly.

LEDs do not produce ozone gas.

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

FAQ

Why and how do I replace a UV led?

Can we visit the factory?

How long will take for mass production?

What materials can UV printers print?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang