WT Offset Printing UV LED Curing System

WT Offset Printing UV LED Curing System

The WT Offset Printing UV LED Curing System by Vtech Co., Ltd is a practical, high-performance solution designed to improve print quality and production efficiency. Since 2006, Vtech has specialized in water-cooled UV and LED curing systems, holding multiple patents and supplying reliable curing units for offset, gravure, flexo and screen printing. WT systems are engineered for easy integration, stable operation and long-term value.

Key Benefits

- Fast, consistent curing: Instant LED output ensures quick drying and stable results across the sheet, reducing smudges and rework.

- Energy-efficient & low heat: LED lamps consume less power and emit less heat, protecting substrates and lowering operational costs.

- Water-cooled reliability: Stable temperature control prolongs lamp life and maintains consistent performance during long runs.

- Easy retrofit & maintenance: Modular design fits most offset presses and simplifies service, minimizing downtime.

- Environmentally friendly: No ozone, fewer hazardous materials, and lower energy use support greener production.

Why Choose WT from Vtech?

Vtech’s experience since 2006 and a portfolio of industry patents ensure you receive proven technology and attentive service. WT systems focus on practical benefits: faster throughput, improved print consistency, lower running costs, and dependable after-sales support. Our team helps with selection, installation and maintenance so you get the best return on investment.

Applications and Value

Ideal for sheetfed offset presses, coatings and specialty applications, the WT UV LED system improves productivity and reduces waste. Whether upgrading an older press or building a new line, WT provides a cost-effective, future-ready curing solution that keeps your operation competitive.

Contact Vtech to discuss how WT can optimize your pressroom — we prioritize clear solutions, reliable performance and long-term support to help you succeed.

Product Images

Our Advantages

Limmediately on and off without preheating. The irradiation intensity can reach 500mw/cm2-- 12000mw/cm2 or higher.

24 Hours Service Hotline: All our team of service are fully conversant with our extensive range of products and can quickly and expertly talk you through any question you may ask. Vtech is committed to provide a 24 hours customer service/breakdown hotline in local office.

Can be designed and customized development, a variety of optical wavelength optional.

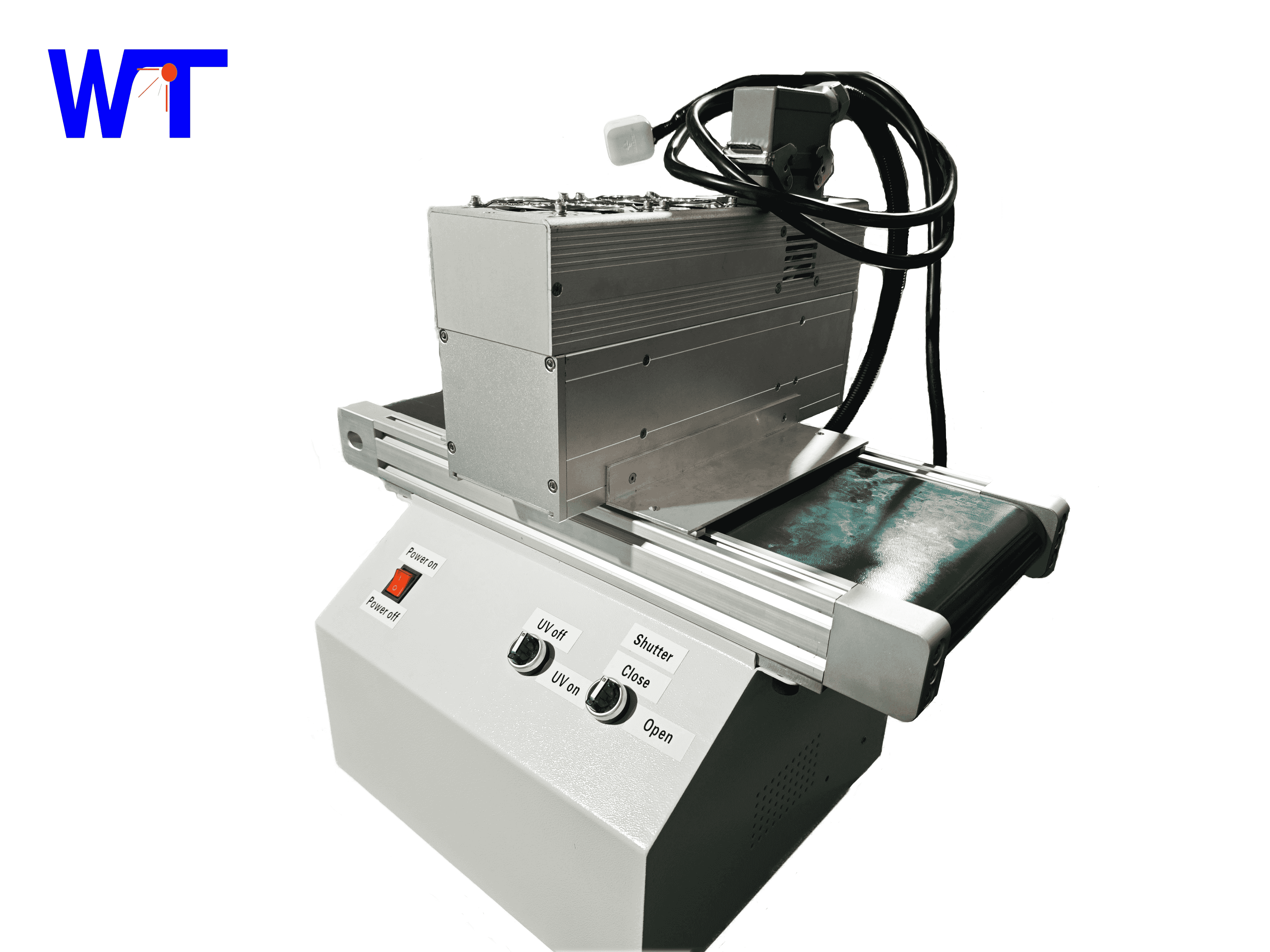

1. The conveyor speed can adjustment according to the products drying condition;

Frequently Asked Questions

Which wavelength do I need?

Can you do a design for me or company?

Why and how do I replace a UV led?

How does your factory do the quality control?

If you have any other questions, please write email to us or call us , we will reply you ASAP.

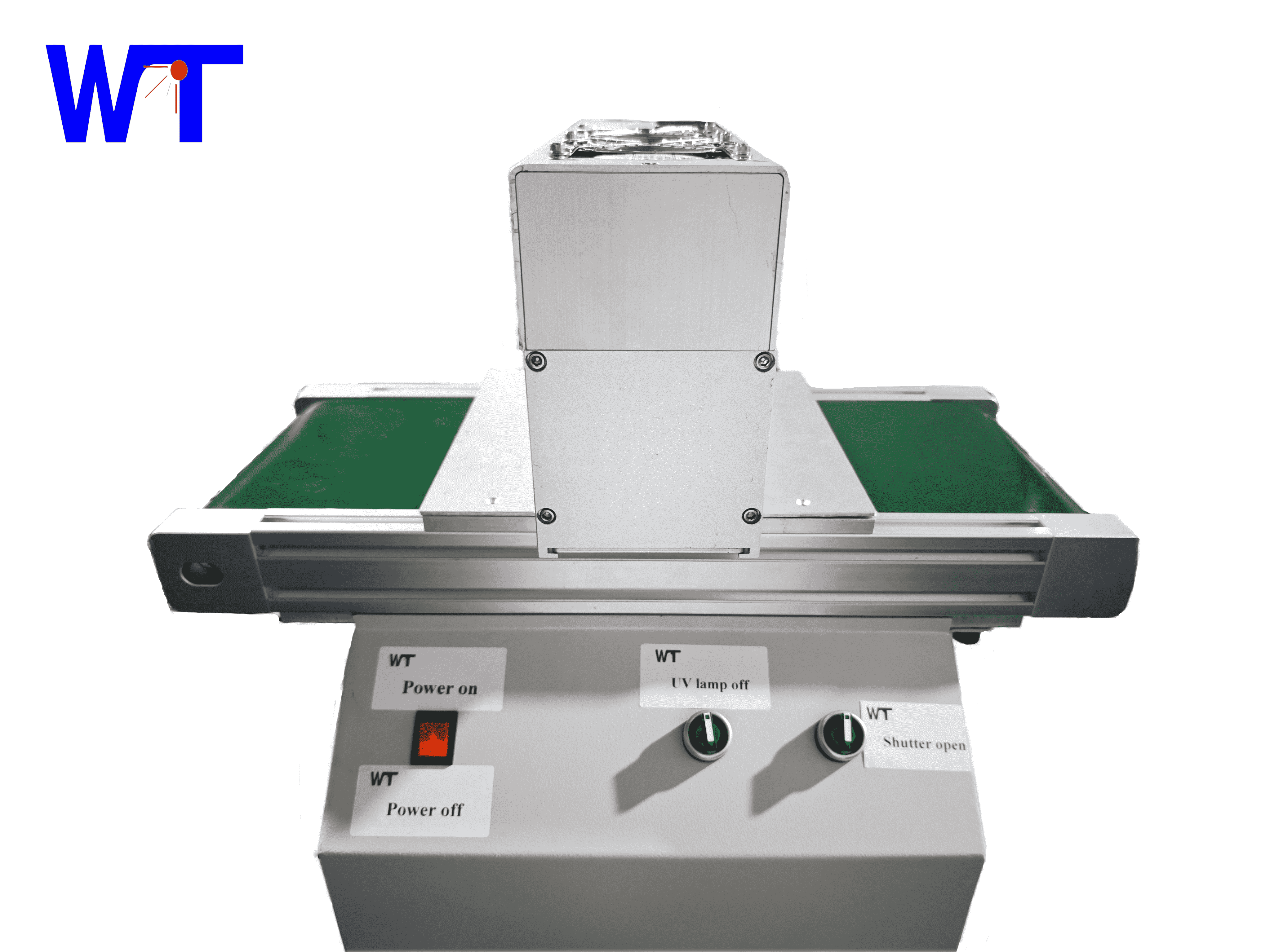

Small UV drying machine

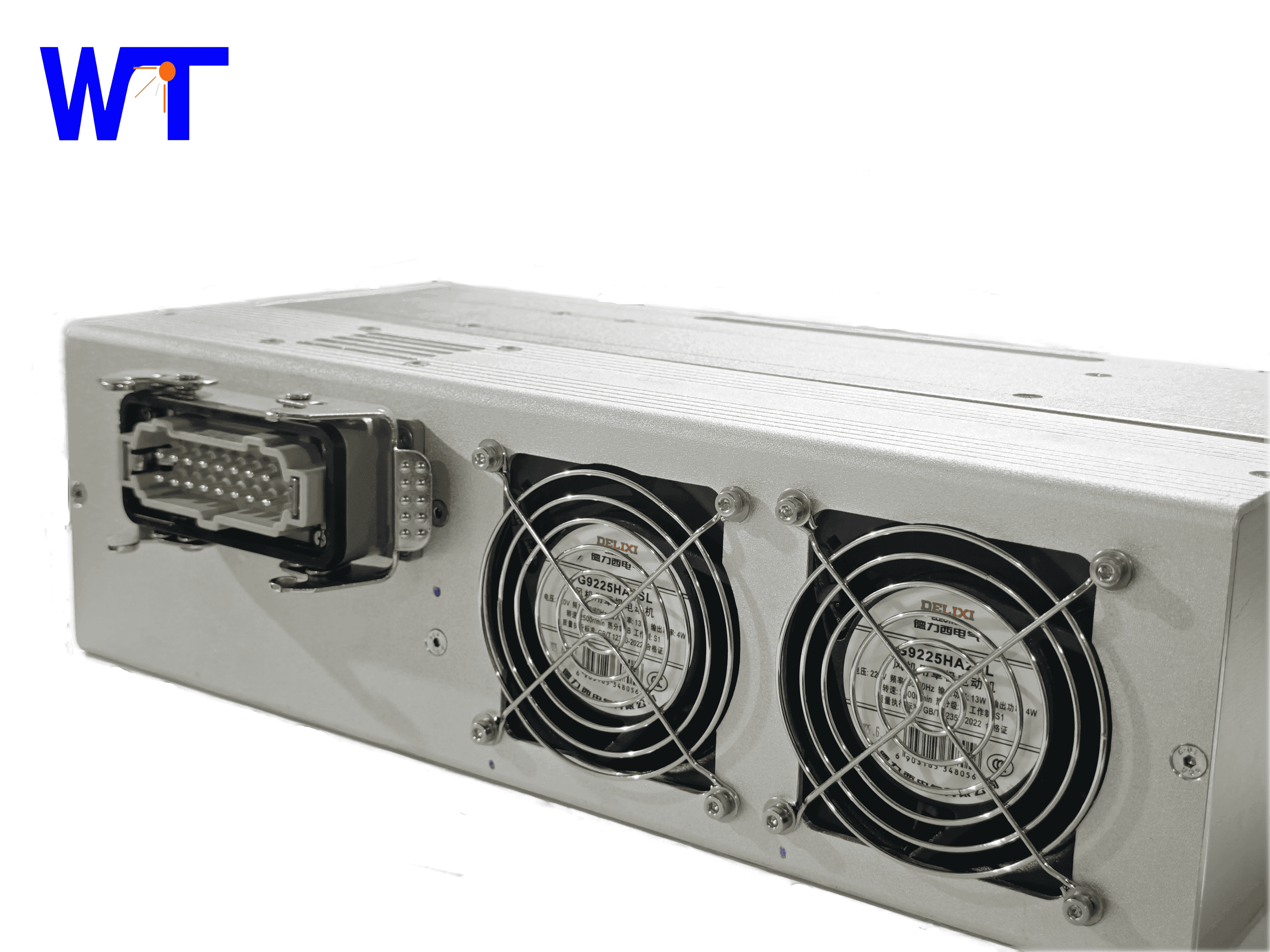

Water-cooled LED curing equipment

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang