WT Mercury UV Curing System for Bobst Flexo Presses | Vtech Co., Ltd

Elevate Your Flexo Printing with WT Mercury UV Curing

In the demanding world of flexographic printing, speed, precision, and quality are paramount. Introducing the WT Mercury UV Curing System, expertly engineered by Vtech Co., Ltd, specifically designed to seamlessly integrate with your Bobst flexo press. Leveraging over 15 years of innovation and patented technology, Vtech brings you a curing solution that not only meets but exceeds industry expectations.

Why Choose WT for Your Bobst Flexo Press?

Unmatched Curing Performance

Experience rapid and consistent ink curing across all applications. Our mercury UV system delivers intense, focused UV energy, ensuring instantaneous drying and a superior, durable finish for every print run. Say goodbye to smudging and hello to vibrant, sharp images that stand out.

Engineered for Bobst Precision

The WT system is meticulously designed for optimal compatibility with Bobst flexographic presses. This integration guarantees peak performance, smooth operation, and reliable results, allowing your press to achieve its full potential without compromise. Benefit from a system built to complement the high standards of Bobst.

Vtech's Legacy of Innovation and Reliability

Since 2006, Vtech Co., Ltd has been at the forefront of UV curing technology. With numerous industry patents and extensive expertise in water-cooled UV and LED UV systems, we stand for reliability and innovation. The WT Mercury UV Curing System embodies this legacy, offering robust construction and consistent performance you can trust, reducing downtime and maintenance.

Enhanced Efficiency and Cost Savings

Achieve higher production speeds with instant curing, significantly improving your throughput. The efficient design of our system helps reduce energy consumption and minimizes waste, leading to tangible cost savings and a more sustainable printing operation. Get more done, faster, and more economically.

Discover the WT Advantage

Upgrade your Bobst flexographic printing capabilities with the WT Mercury UV Curing System. Partner with Vtech Co., Ltd to enhance print quality, boost productivity, and secure a competitive edge. Contact us today to learn how our proven technology can transform your operations.

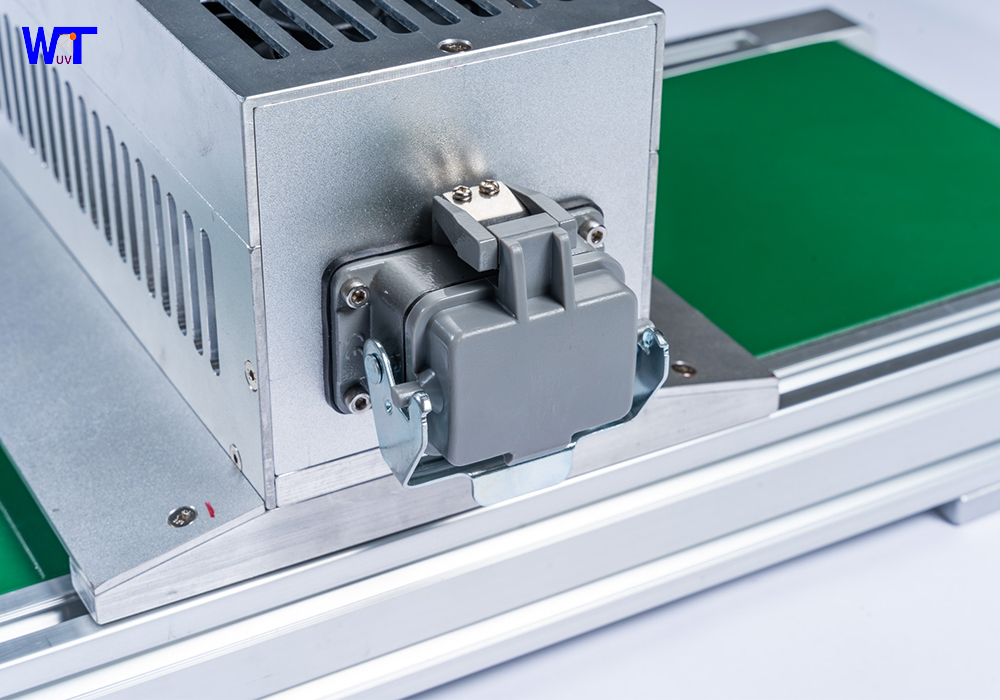

Product Images

Advantages

Compact size, making it easy to integrate into fully automated production lines and equipment.

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

With stepless dimming function;

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

Question you may concern

Are you a trader or manufacturer?

How about the after service?

Why choose Vtech's UV LED curing machine?

What's the Peak Irradiance do I need?

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang