WT LED UV Curing System for Offset Presses

Product Overview

WT LED UV Curing System for Offset

The WT LED UV curing system is designed specifically for offset presses to provide fast, consistent curing with lower energy use and minimal maintenance. It fits inline with existing equipment and gives stable, repeatable results for a wide range of inks and coatings.

Key Features

Energy Efficiency

Using long-life LEDs, WT systems consume far less power than traditional lamps. This reduces operating cost and heat load on the press, helping protect sensitive substrates and reducing cooling needs.

Fast and Uniform Curing

High-intensity LED arrays deliver quick, even curing across the web or sheet. Faster cure times mean higher throughput and fewer production bottlenecks.

Easy Integration and Control

The compact design and adaptable mounts make installation on most offset presses straightforward. Intuitive controls let operators adjust intensity and speed to match job requirements without complex setup.

Durable and Low Maintenance

LEDs offer long life and stable output with minimal upkeep. The system is built for continuous industrial use, reducing downtime and service interruptions.

Applications & Benefits

Practical Uses

Ideal for sheetfed and web offset printing, the WT LED UV system works well with varnishes, coatings, and various UV inks. It improves gloss, adhesion, and resistance properties, supporting consistent quality across runs.

Value for Your Business

Adopting WT LED curing can lower energy bills, speed up production, and reduce waste from mis-cures. Reliable performance and simple operation help printers deliver on time and maintain customer satisfaction.

About Vtech (WT)

Vtech Co., Ltd, established in 2006, specializes in water-cooled and LED UV curing systems. With multiple industry patents and broad experience across offset, gravure, flexo, coating and silk-screen applications, Vtech offers dependable products and responsive service to keep your production efficient.

Ready to Improve Your Press

Choose WT LED UV curing systems for a practical, cost-effective upgrade. Contact us to discuss compatibility, sample tests, and service options so you can confidently enhance print quality and throughput.

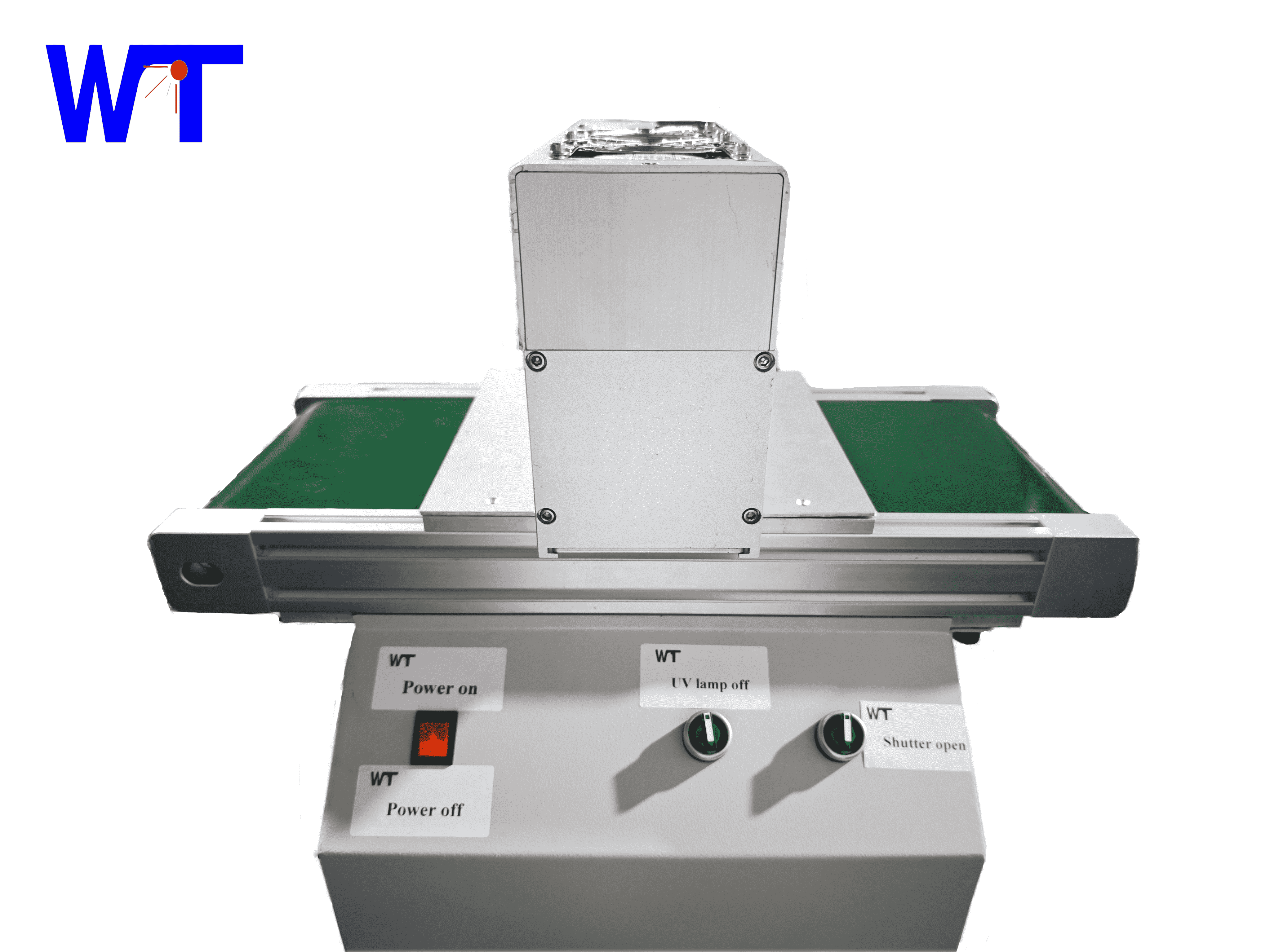

Picture Show

Advantages

LEDs do not produce ozone gas.

Limmediately on and off without preheating. The irradiation intensity can reach 500mw/cm2-- 12000mw/cm2 or higher.

Compact size, making it easy to integrate into fully automated production lines and equipment.

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

Q&A

Where is your factory located?

Why and how do I replace a UV led?

Which wavelength do I need?

What's the Peak Irradiance do I need?

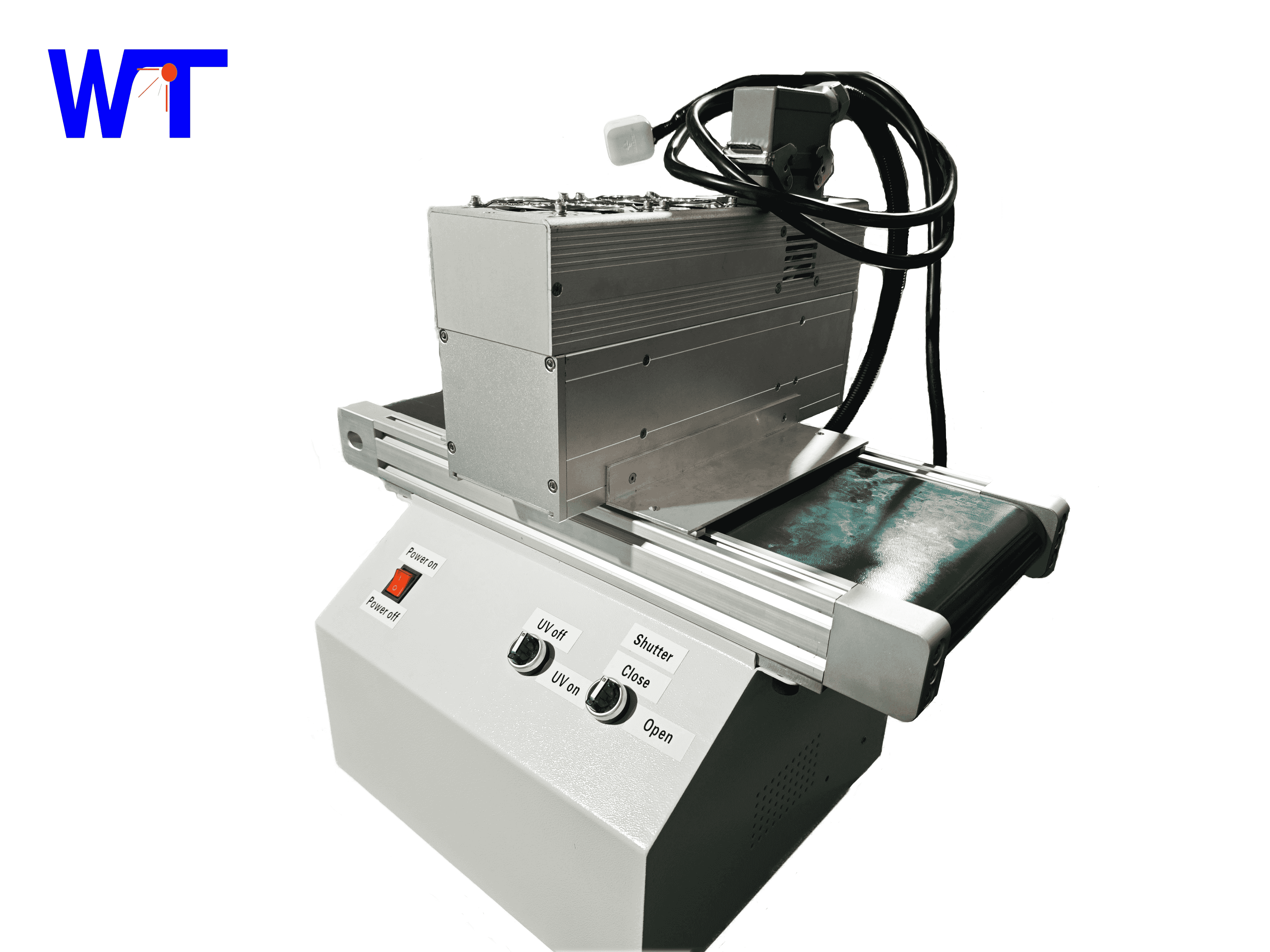

Small UV drying machine

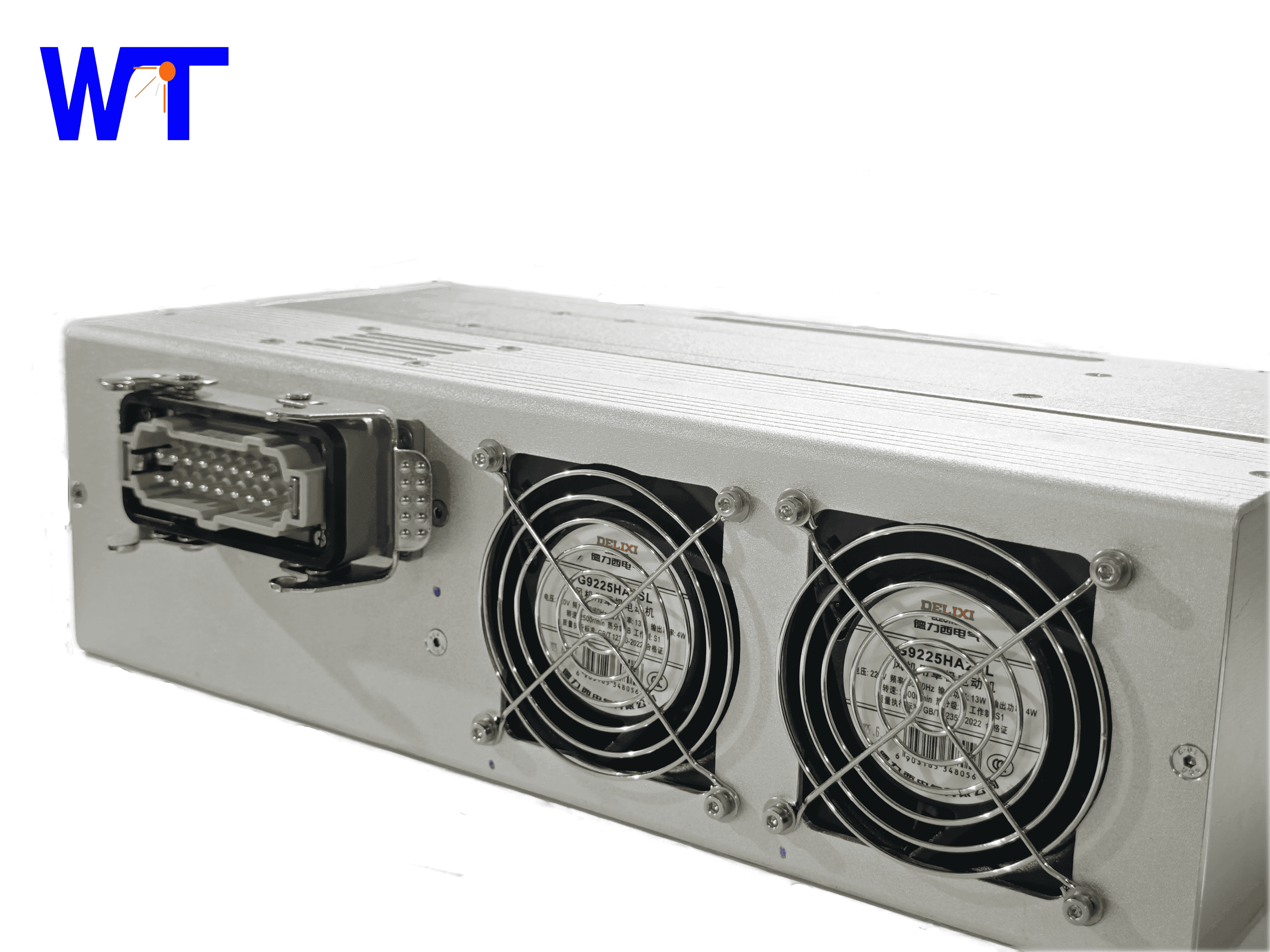

Water-cooled LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang