WT LED UV Curing Light — Reliable UV Curing System

Overview

The WT curing light from Vtech Co., Ltd is a professional LED UV curing system designed for printing and coating applications. Founded in 2006, Vtech specializes in water-cooled and LED UV curing systems with numerous industry patents. WT units are built for consistent performance, easy integration, and long-term reliability.

Key Features

High Efficiency and Fast Curing

WT LED UV lights deliver concentrated UV energy for rapid curing. Faster curing reduces production time and improves throughput without compromising finish quality.

Water-Cooled and Air-Cooled Options

Choose water-cooled models for heavy-duty, continuous operation or air-cooled models for lighter workloads. Both types are designed to keep the LED modules stable and extend service life.

Durable and Patented Design

With multiple patents, WT curing lights offer a robust design that resists wear in demanding pressroom environments. Durable components mean fewer interruptions and lower maintenance costs.

Applications

WT curing lights are ideal for:

- Offset printing

- Flexographic and gravure presses

- Screen printing and coatings

- Industrial finishing and adhesive curing

Why Choose WT?

WT systems combine industry experience, patented technology, and practical engineering. They provide consistent curing, reduced energy use, and simplified maintenance. This makes them a trusted choice for manufacturers seeking reliable, repeatable results.

Support, Safety, and Installation

Easy Integration

WT curing lights are designed for straightforward installation and can be adapted to existing press lines. Clear documentation and flexible mounting options help minimize downtime.

Safety and Service

Vtech emphasizes operator safety with shielding and interlocks. Professional global support and spare parts availability ensure fast service and ongoing performance.

Technical Summary

Typical specs include high-output LED modules, selectable cooling options, adjustable intensity controls, and long mean time between failures (MTBF). Contact Vtech for model-specific specifications and customization options.

Choose WT LED UV curing lights for proven reliability, energy efficiency, and expert support from a company with deep industry knowledge and patented solutions.

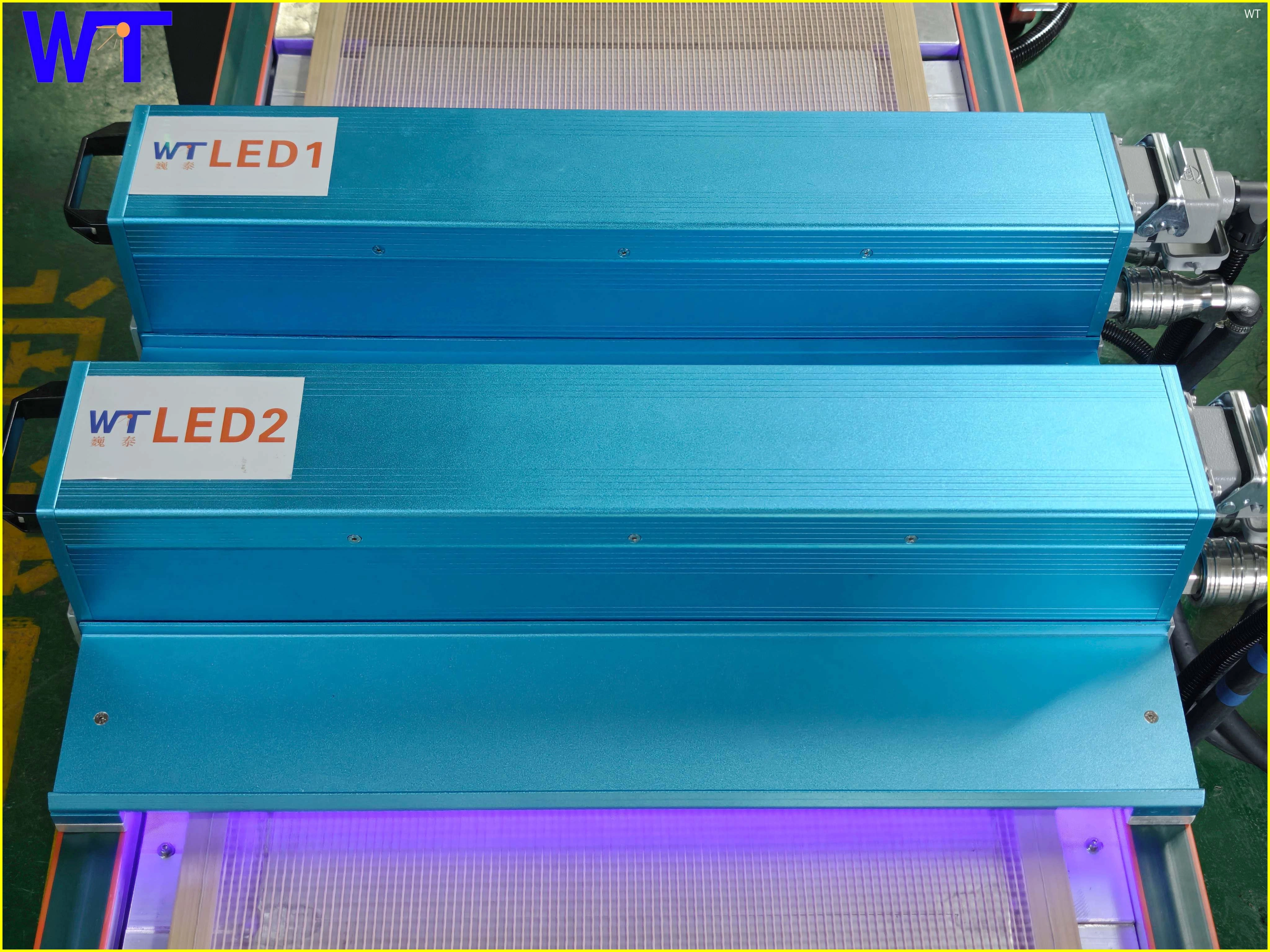

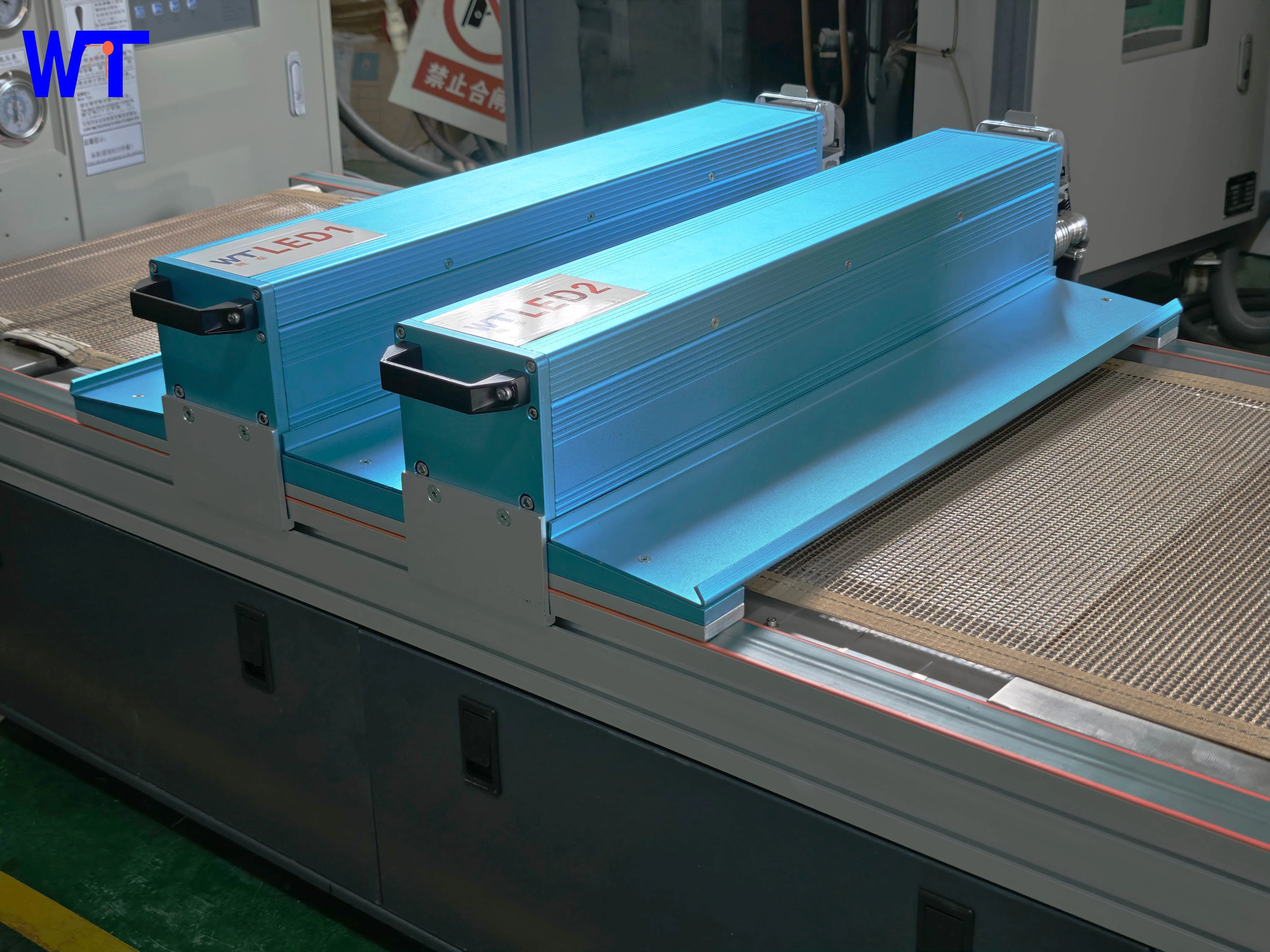

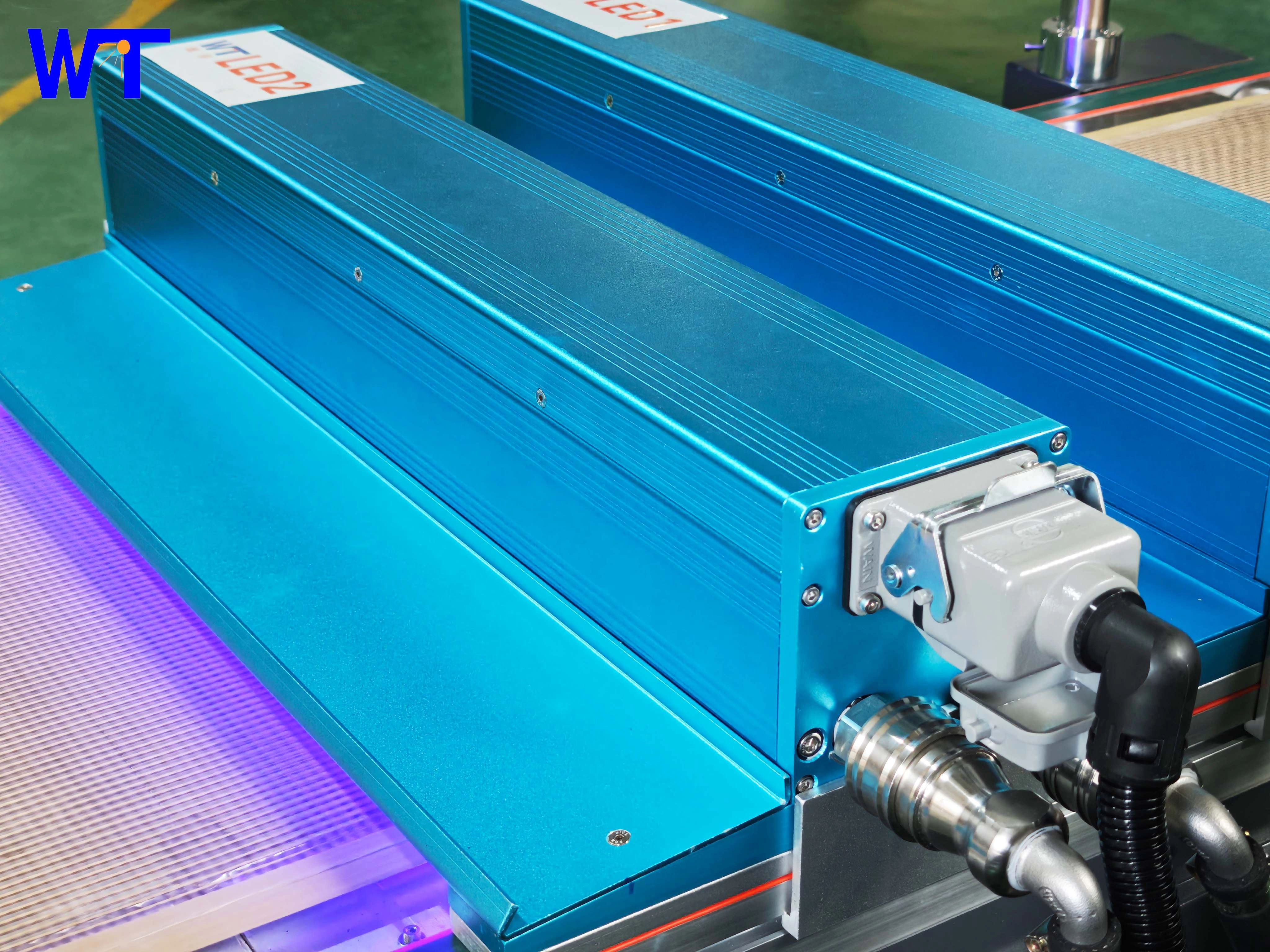

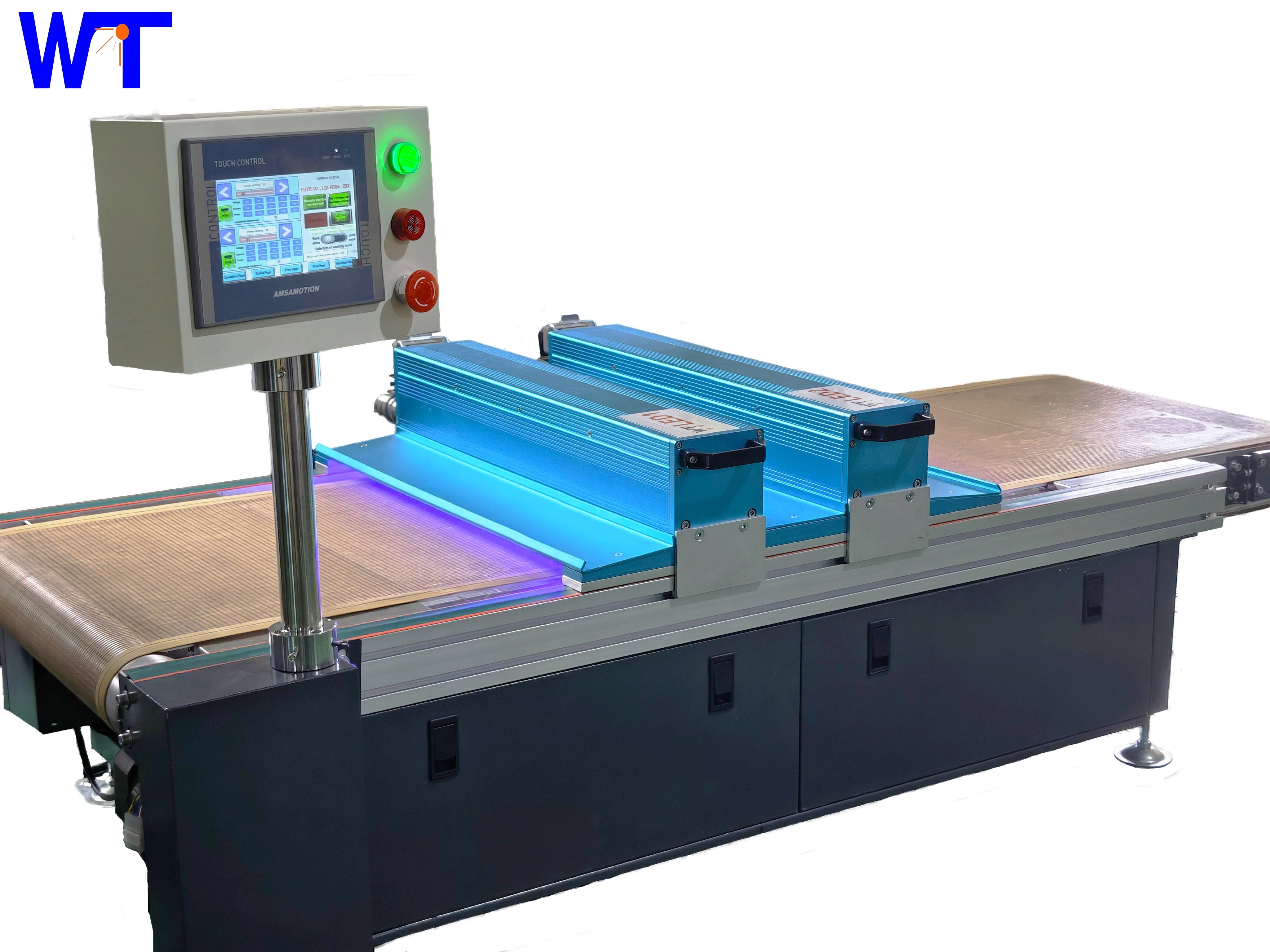

Picture Show

Our Advantages

Can be designed and customized development, a variety of optical wavelength optional.

It adopts special military-grade UVLED constant current power supply, which has intact short circuit protection, leakage protection, overcurrent and overvoltage protection, and undervoltage protection.

With line disconnection alarm and LED dead point detection alarm function.

Limmediately on and off without preheating. The irradiation intensity can reach 500mw/cm2-- 12000mw/cm2 or higher.

Frequently Asked Questions

Which wavelength do I need?

How about the after service?

Can we visit the factory?

What materials can UV printers print?

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

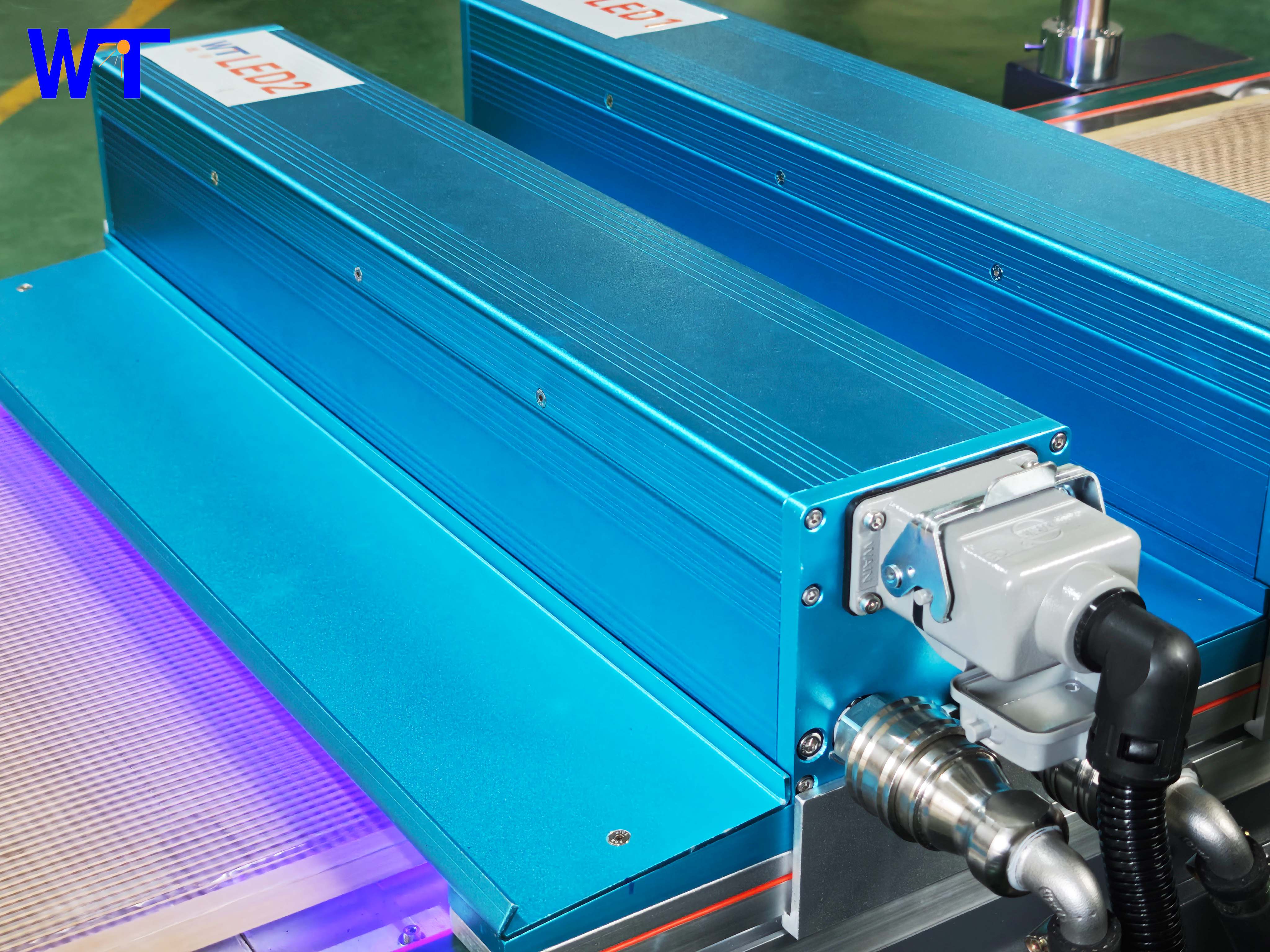

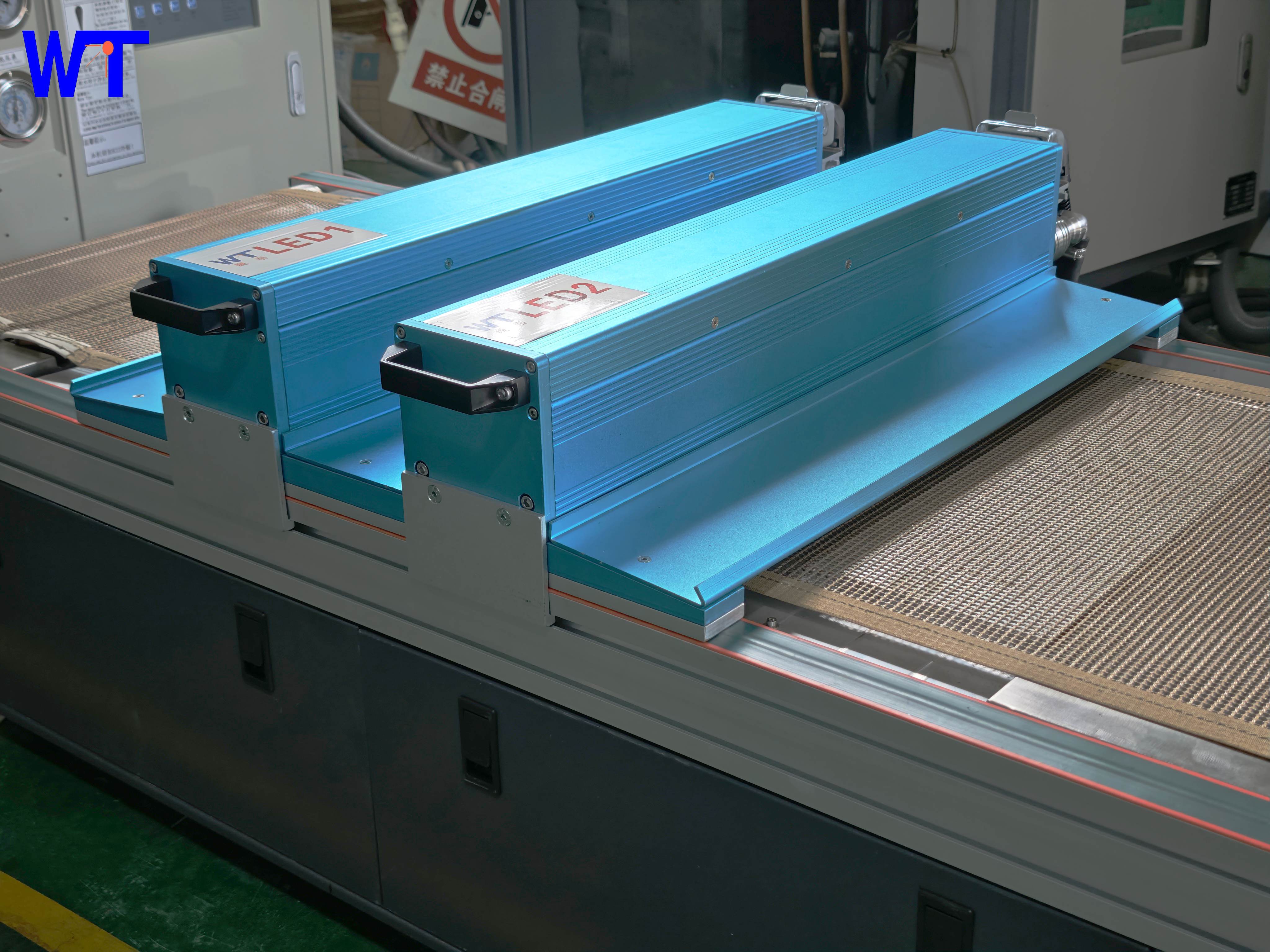

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang