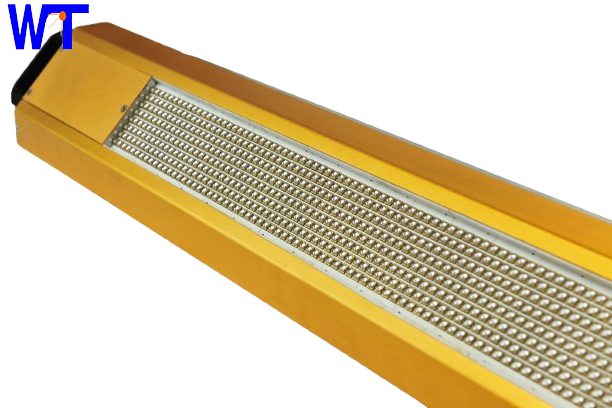

WT High Power UV LED Curing System: Elevate Your Production

Introducing the WT High Power UV LED Curing System: Redefining Industrial Efficiency

In today's fast-paced industrial landscape, efficiency and quality are paramount. The WT High Power UV LED Curing System, from industry leader Vtech Co., Ltd., is engineered to meet these demands head-on. Designed for peak performance, this system offers a revolutionary approach to curing, empowering businesses to achieve superior results with unprecedented speed and cost-effectiveness.

Unleash Unmatched Performance and Efficiency

The WT High Power UV LED Curing System represents the pinnacle of modern curing technology. Engineered for demanding industrial environments, our system delivers instant, complete curing, dramatically accelerating your production cycles. Say goodbye to bottlenecks and lengthy drying times; with WT, you achieve immediate readiness for subsequent processes, significantly boosting throughput. Furthermore, our cutting-edge LED technology consumes substantially less energy than traditional UV lamps, translating into remarkable cost savings on utilities and a reduced carbon footprint, aligning with sustainable operational goals.

Versatility Engineered for Your Specific Needs

Leveraging Vtech's extensive experience and numerous industry patents since 2006, the WT system is not just powerful but also incredibly adaptable. Whether your application is in high-speed offset press printing, intricate gravure or flexo press work, precise coating applications, or vibrant silk screen printing, our solutions are meticulously engineered to integrate seamlessly. This versatility ensures consistent, superior curing across a diverse array of substrates and inks, guaranteeing outstanding print quality, enhanced durability, and improved adhesion for all your products.

The Vtech Advantage: Innovation, Reliability, and Partnership

Choosing WT means investing in a legacy of innovation and reliability. Vtech Co., Ltd., established in 2006, has consistently been at the forefront of UV and LED curing system development. Our commitment to research and development, evidenced by our portfolio of patents, ensures you receive state-of-the-art technology. We don't just supply equipment; we offer a partnership. Our rich experience and deep expertise mean we provide reliable service and efficient solutions tailored to your unique production challenges, ensuring your continued success and competitive edge in the market.

Detailed display

Our Advantages

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

Light source independent packaging(COB), long service life,energy saving, environ-ment friendly.

It adopts special military-grade UVLED constant current power supply, which has intact short circuit protection, leakage protection, overcurrent and overvoltage protection, and undervoltage protection.

Can be designed and customized development, a variety of optical wavelength optional.

Frequently Asked Questions

Can I use my own PLC and Electric cabinet?

How about the after service?

How long will take for mass production?

Why and how do I replace a UV led?

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang