WT Fusion UV Curing System

WT Fusion UV Curing System — Reliable Curing for Modern Production

The WT Fusion UV curing system by Vtech Co., Ltd combines proven water-cooled and LED UV technologies to give stable, fast, and consistent curing for a wide range of industrial applications. Designed for easy integration into offset, gravure, flexo, coatings, and silk screen printing lines, this system helps manufacturers increase output quality and reduce downtime.

Why choose WT Fusion?

- Energy-efficient: Advanced LED and optimized water-cooled lamps reduce power use and operating cost.

- Stable performance: Patented designs and precise temperature control ensure consistent curing across long runs.

- Easy integration: Compact modules and flexible mounting make installation quick on new or existing lines.

- Low maintenance: Durable components and straightforward servicing minimize production interruptions.

Key benefits for your production

With WT Fusion, you get faster curing speeds and improved surface finish, which increases throughput and reduces rework. The system’s efficient heat management protects sensitive substrates and inks, while LED options lower long-term energy and replacement costs. Vtech’s many years of experience and industry patents mean you receive a mature product backed by professional support.

Applications and compatibility

WT Fusion fits a wide variety of processes: offset presses, gravure and flexo presses, coating lines, and screen printing. It handles different substrates—paper, film, foil, and board—making it a versatile choice for converters, printers, and coating houses.

About Vtech Co., Ltd

Founded in 2006, Vtech specializes in research, development, and manufacturing of water-cooled and LED UV curing systems. With multiple industry patents and extensive field experience, Vtech delivers reliable equipment and responsive service to support efficient production and long-term value.

Choose WT Fusion UV curing system for dependable curing, simpler operation, and measurable production gains.

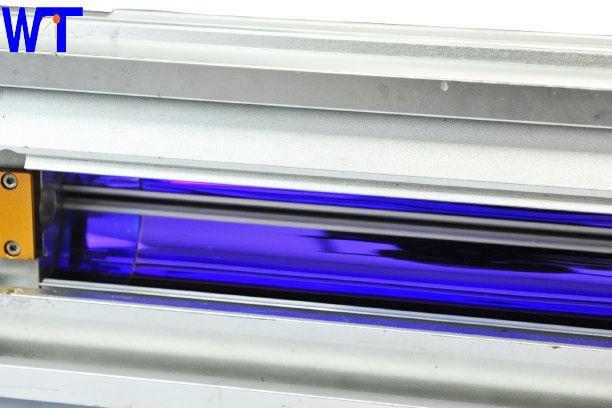

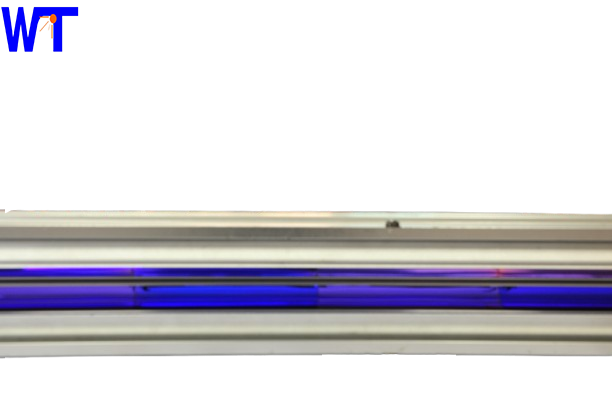

Product Image

Our Advantages

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

Compact size, making it easy to integrate into fully automated production lines and equipment.

Limmediately on and off without preheating. The irradiation intensity can reach 500mw/cm2-- 12000mw/cm2 or higher.

LEDs do not produce ozone gas.

FAQ

lf the light intensity is adjustable?

How long will take for mass production?

how can we guarantee quality?

How to cooperate with you and what is the cooperation process?

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Water-cooled LED curing equipment

Small UV drying machine

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang