WT edale fl12 UV Curing System: Transform Your Production

Elevate Your Production with the WT edale fl12 UV Curing System

In today's fast-paced production environment, efficiency, quality, and reliability are paramount. The WT edale fl12 UV Curing System, from industry leader Vtech Co., Ltd, is engineered to meet these demands head-on. Designed for unparalleled performance, the edale fl12 offers a transformative solution for businesses seeking to optimize their printing and coating processes.

Precision & Speed: high quality Curing Performance

Experience the next level of operational excellence with the edale fl12. This advanced UV curing system delivers rapid, consistent, and reliable curing, significantly reducing drying times and accelerating your production throughput. Achieve superior adhesion, vibrant color reproduction, and durable, high-quality finishes that impress. The WT edale fl12 ensures precise energy delivery, optimizing every curing cycle for consistent, flawless results, every time.

Built for Versatility Across Industries

The WT edale fl12 is a versatile powerhouse, seamlessly integrating into a wide range of applications. Whether you're operating offset, gravure, flexo, or silk screen presses, or applying various coatings, the edale fl12 is designed to enhance your process. Its adaptability makes it the ideal choice for diverse industries looking for a reliable and high-performance curing solution that meets specific operational needs.

The Vtech Difference: Innovation You Can Trust

As a specialist in UV and LED curing systems since 2006, Vtech Co., Ltd, the parent company of the WT brand, brings extensive expertise and innovation to every product. With numerous patents and a deep understanding of curing technology, Vtech ensures that the edale fl12 is not just a product, but a solution built on a foundation of proven research and development.

Engineered for Efficiency and Reliability

The WT edale fl12 UV Curing System benefits from Vtech's commitment to water-cooled and LED UV technologies, ensuring a robust, long-lasting, and energy-efficient system. Its reliable design minimizes downtime and maintenance, allowing your operations to run smoothly and consistently. Invest in the edale fl12 to leverage Vtech's rich experience and expertise, guaranteeing you efficient production and dependable service.

Ready to boost your productivity and achieve superior quality? Discover how the WT edale fl12 UV Curing System can revolutionize your operations. Contact us today to learn more.

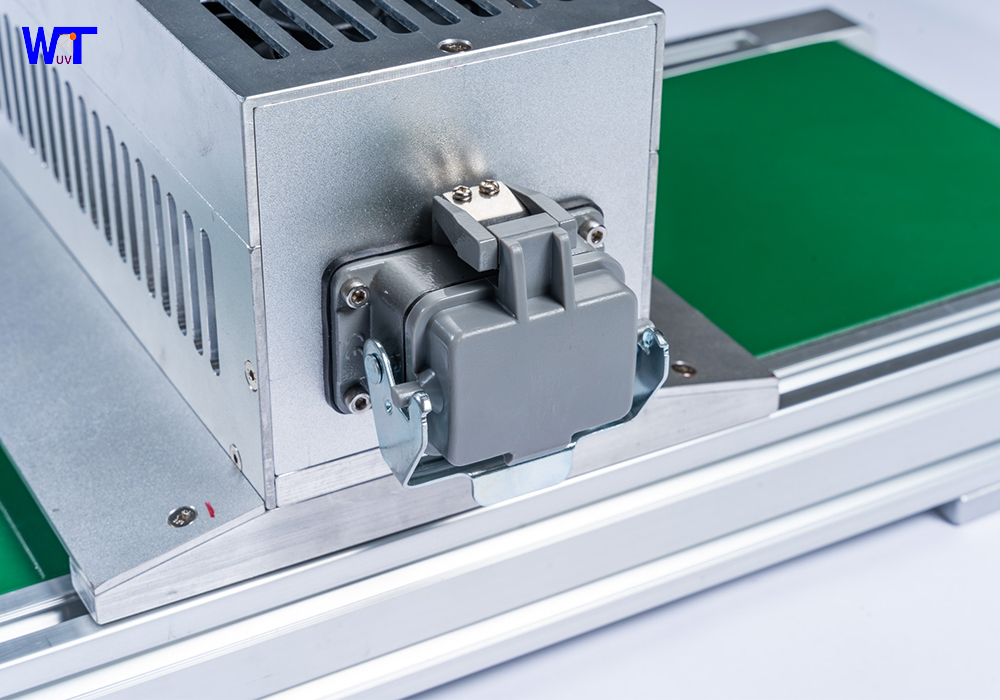

Product Images

Our Advantages

24 Hours Service Hotline: All our team of service are fully conversant with our extensive range of products and can quickly and expertly talk you through any question you may ask. Vtech is committed to provide a 24 hours customer service/breakdown hotline in local office.

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

The operation interface is simple, the sound and light alarm corresponds to the light source module, and the fault can be quickly determined.

Q&A

What's the Peak Irradiance do I need?

What's the cooling way?

Are you a trader or manufacturer?

What materials can UV printers print?

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang