WT Bobst Mercury UV Curing System — Reliable Curing for Printing Presses

Overview

The WT Bobst Mercury UV curing system is a water-cooled UV and LED curing unit designed for use with Bobst Mercury printing presses. Manufactured by Vtech Co., Ltd., established in 2006, this system blends proven patents and real-world printing experience to deliver consistent, high-speed curing for offset, gravure, flexo, coatings, and silk screen jobs.

Why Choose WT Mercury UV System

Our system focuses on simple operation, steady performance, and long-term reliability. It offers a compact footprint, quick installation, and low maintenance. Operators will appreciate predictable curing, reduced downtime, and fewer rejects—helping your production stay on schedule and under budget.

Key Features

- Water-cooled design for stable lamp temperature and extended lamp life.- Available in both traditional mercury UV and LED UV options to match inks and workflows.- Compatible with Bobst Mercury printing presses and popular press lines.- Patented components and controls developed by Vtech for consistent output.- Easy-to-use controls and safety interlocks for operator peace of mind.

Benefits for Your Shop

- Faster curing and increased press speed, improving throughput.- Uniform curing across different substrates reduces rework.- Lower operating costs thanks to efficient cooling and optional LED technology.- Reliable support from Vtech’s experienced engineering and service team.- Flexible configurations for coatings, varnish, and specialty applications.

Support and Service

Vtech Co., Ltd. has been specializing in water-cooled and LED UV systems since 2006. With multiple patents and a deep industry background, Vtech offers installation guidance, routine maintenance, spare parts, and technical training. Our goal is to keep your WT Mercury system running smoothly so your press meets production targets.

Conclusion

The WT Bobst Mercury UV curing system is a dependable choice for printers seeking consistent, efficient curing on Bobst Mercury presses. With Vtech’s patented technology and hands-on support, you get a solution that is easy to use, low maintenance, and built to last.

Product Images

Our Advantages

UV energy uniformity ≥ 98%.

With line disconnection alarm and LED dead point detection alarm function.

Can be designed and customized development, a variety of optical wavelength optional.

LEDs do not produce ozone gas.

Question you may concern

Can I use my own PLC and Electric cabinet?

lf the light intensity is adjustable?

Why choose Vtech's UV LED curing machine?

What is the major advantages of UV LED curing system’s than other UV curing system?

If you have any other questions, please write email to us or call us , we will reply you ASAP.

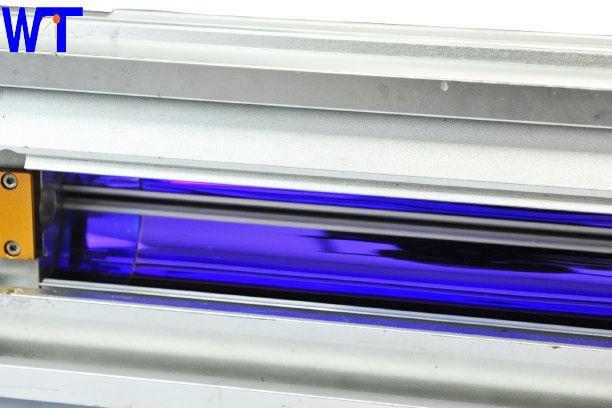

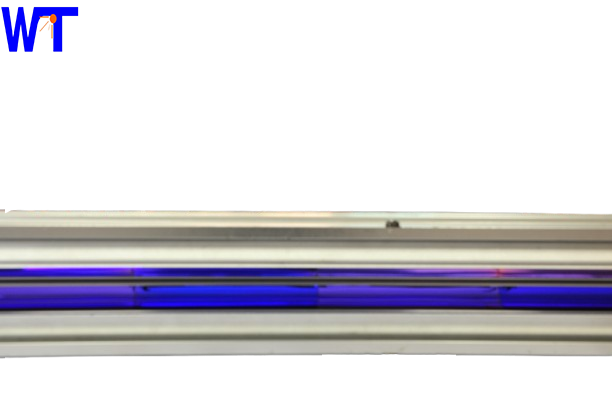

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Small UV drying machine

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang