WT Bobst Flexography UV Curing System — Reliable UV Cure for Flexo Presses

Product Overview

The WT Bobst Flexography UV Curing System is designed to bring consistent, high-speed curing to flexo presses. Built by Vtech Co., Ltd — an experienced manufacturer since 2006 — this system combines proven water-cooled UV and advanced LED UV options to meet different production needs. It is ideal for label, package, and narrow-web flexo jobs where speed, reliability, and print quality matter.

Key Features

- Water-cooled and LED modules for stable temperature control and long lamp life.

- Even, reliable curing that reduces set-off and increases throughput.

- Easy integration with Bobst flexo presses and common flexo workflows.

- Compact design for minimal footprint and quick maintenance access.

- Patented technology from Vtech to ensure consistent performance.

Benefits for Your Production

This curing system improves job turnarounds and reduces waste. Faster cure times mean higher productivity. Uniform curing lowers reprints and customer complaints. Energy-efficient LED options reduce power use and operating costs. Simple controls and fast lamp replacement keep your press running longer with less downtime.

Why Choose WT and Vtech

Vtech Co., Ltd has specialized in water-cooled and LED UV curing systems since 2006. With multiple industry patents, Vtech delivers solutions for offset, gravure, flexo, coatings, and screen printing. Choosing WT means getting reliable equipment plus responsive service and technical support to keep your production efficient.

Customer-Focused Support

We value every customer. Our team offers installation guidance, prompt spare parts supply, and practical maintenance tips. This ensures your WT Bobst Flexography UV Curing System performs well from day one and throughout its service life.

Summary

The WT Bobst Flexography UV Curing System is a practical, value-driven choice for flexo printers seeking faster curing, better print consistency, and lower operating costs. Backed by Vtech’s experience and patents, it integrates smoothly into Bobst presses and supports reliable, high-quality production.

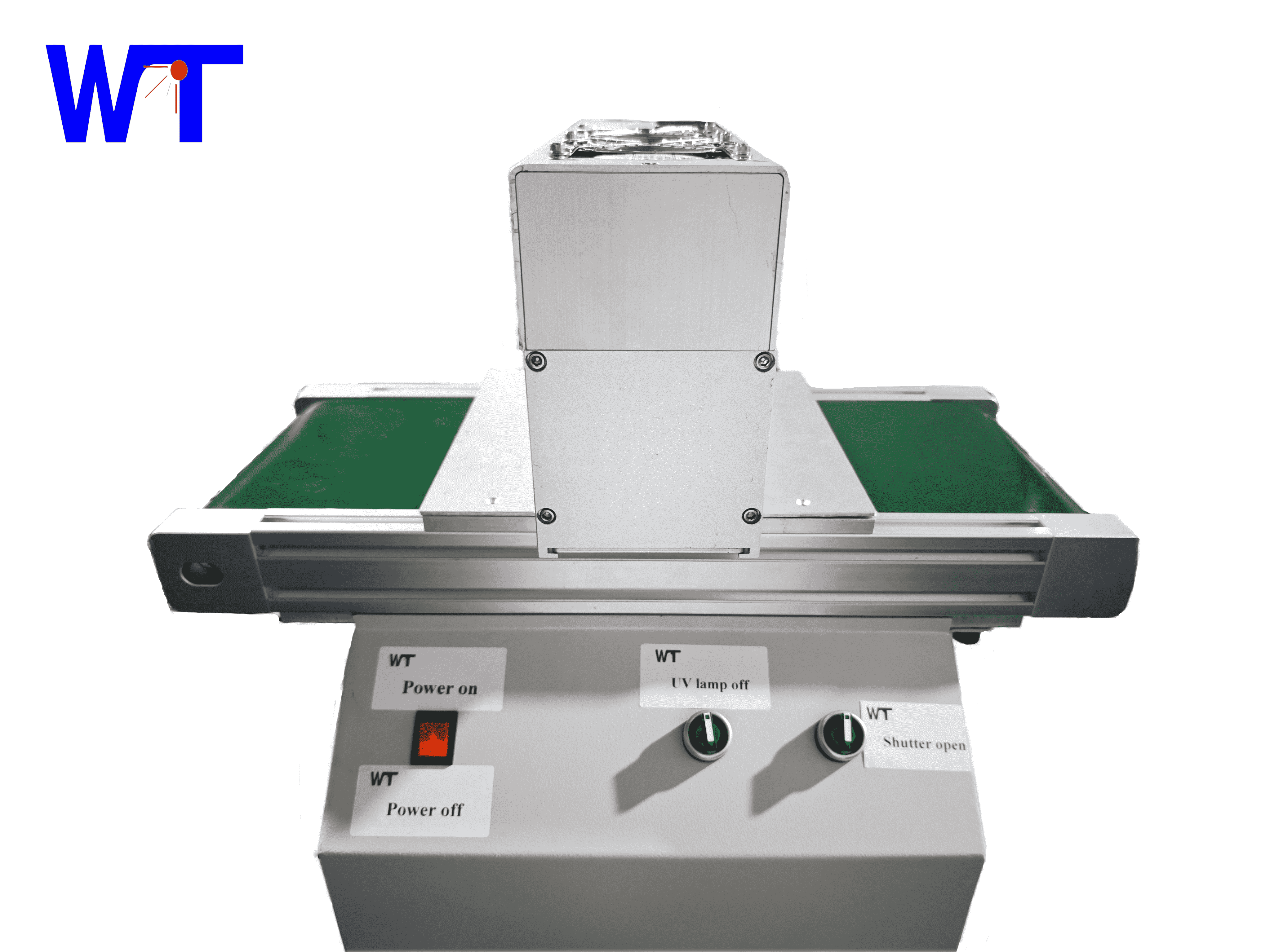

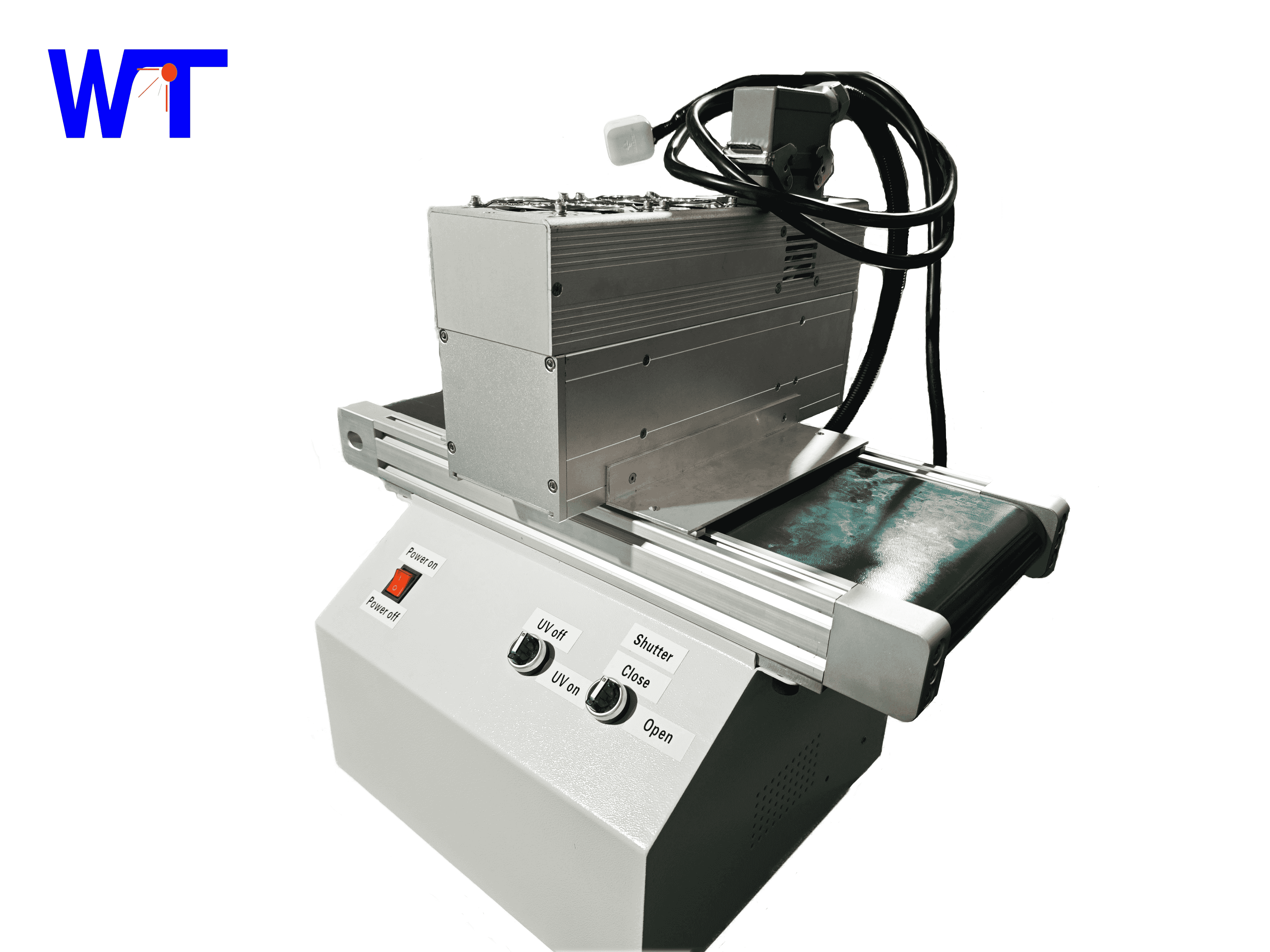

Picture Show

Our Advantages

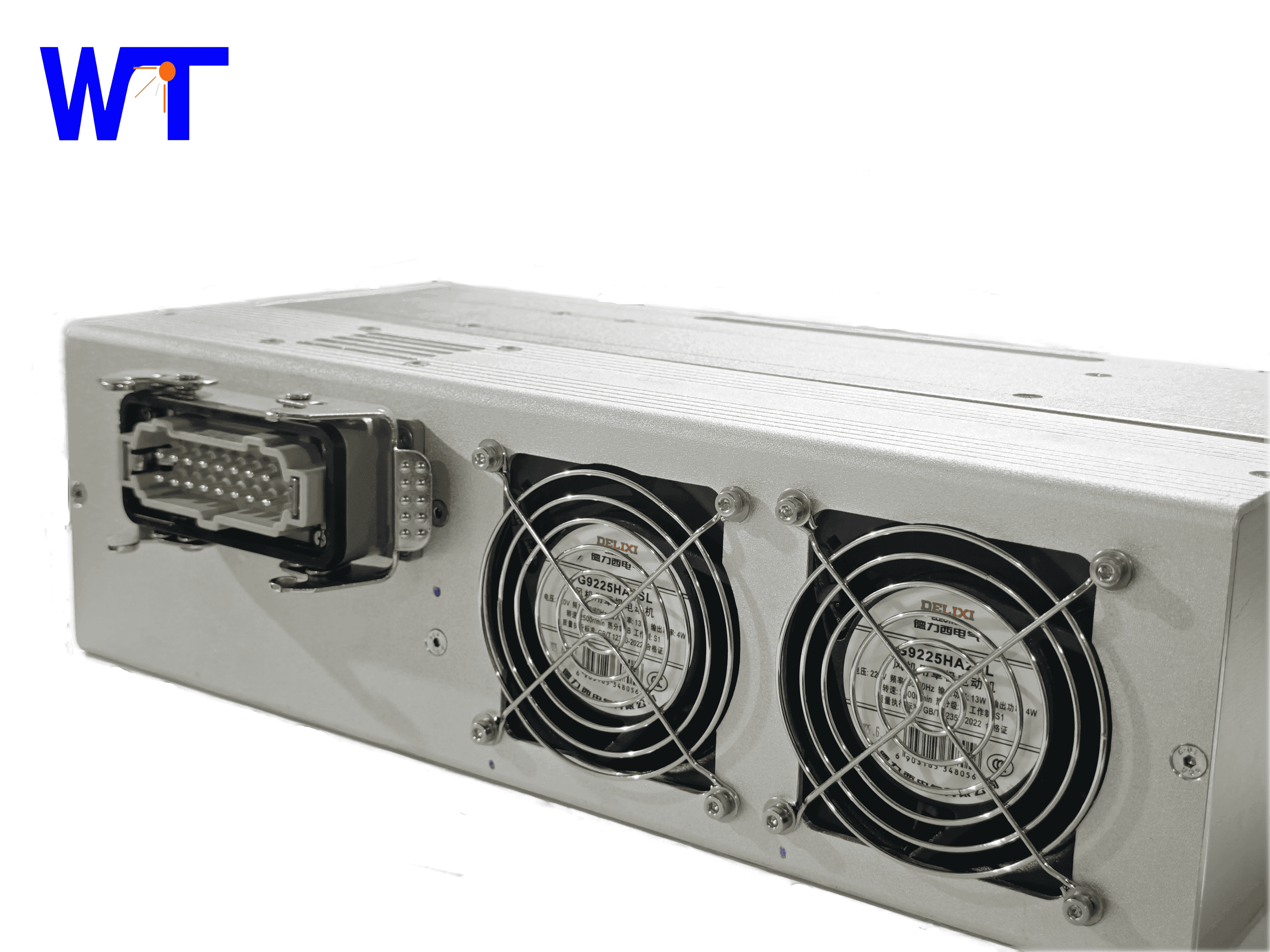

It adopts special military-grade UVLED constant current power supply, which has intact short circuit protection, leakage protection, overcurrent and overvoltage protection, and undervoltage protection.

1. The conveyor speed can adjustment according to the products drying condition;

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

With stepless dimming function;

Q&A

How long will take for mass production?

lf the light intensity is adjustable?

Can I use my own PLC and Electric cabinet?

When can I get the quotations?

Small UV drying machine

Customized conveyor belt type UV LED curing equipment

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang