High-Quality UV Gravure Ink by WT for Professional Printing

Discover the future of printing with WT's High-Quality UV Gravure Ink. Renowned for its high-quality formulation, this ink is designed to offer unparalleled performance and reliability for your printing needs. Whether you're printing on paper, film, or foil, WT UV Gravure Ink ensures vibrant color reproduction and excellent adhesion, even on challenging substrates.

Our UV Gravure Ink is crafted to meet the highest industry standards, providing superior gloss and fast curing times that enhance production efficiency without compromising on quality. With a commitment to environmental sustainability, WT utilizes eco-friendly ingredients in our formulations, ensuring that your printing process is not only effective but also responsible.

Professionals trust WT for its consistent results and innovation in ink technology. Our UV Gravure Ink is rigorously tested for compatibility across various printing equipment, making it an ideal choice for both short and long production runs. Experience peace of mind with WT’s dedicated customer support, always ready to assist you in achieving optimal printing results.

Choose WT's UV Gravure Ink for its outstanding performance, durability, and ease of use, ensuring that your products stand out with precision and clarity. Make the switch today and align your business with a brand known for excellence and reliability in the printing industry.

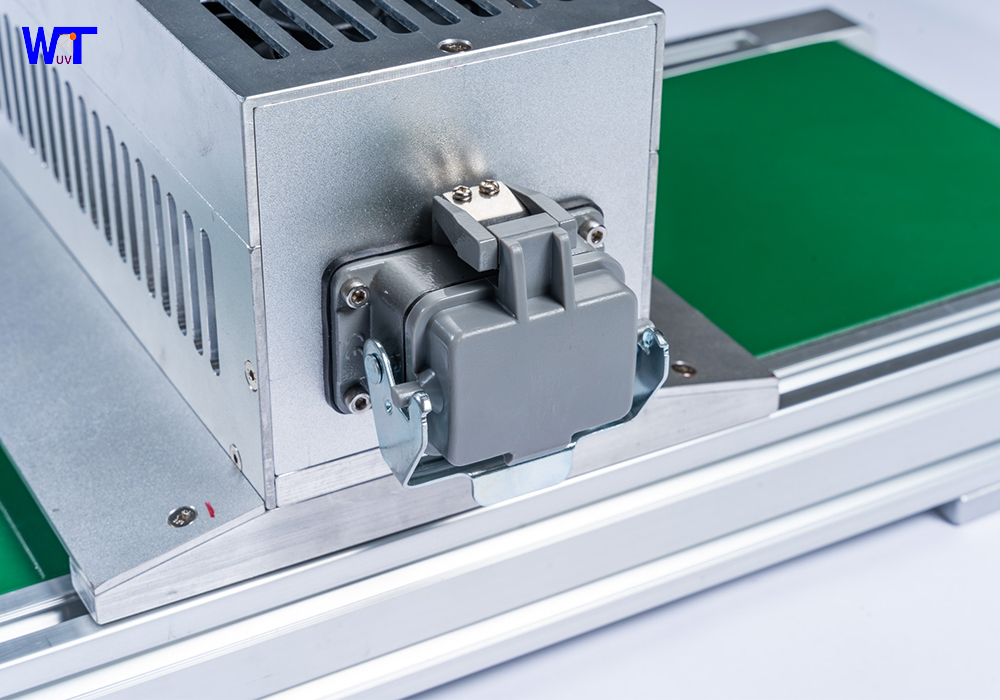

Picture Show

Advantages

Light source independent packaging(COB), long service life,energy saving, environ-ment friendly.

We are the source factory with professional R&D team and skilled workers.

We have over 17 years experience in UV curing industry.

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

FAQ

When can I get the quotations?

How long will take for mass production?

Can I use my own PLC and Electric cabinet?

What should I do when I don’t really know how to setting the printer parameters?

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Small UV drying machine

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang