can you cure opi gel with uv lamp | WT Guide

Can You Cure OPI Gel With a UV Lamp? WT

Understanding OPI Gel Curing

* Specific Wavelengths Matter: OPI Gel polishes are formulated to cure under specific UV/LED light wavelengths. While many UV lamps work, using the *correct* one is vital for complete curing. Insufficient curing leads to weak, easily chipped nails.

* UV vs. LED Lamps: Both UV and LED lamps can cure OPI Gel. However, LED lamps are generally preferred for their faster curing times and longer lifespan. OPI recommends using an LED lamp specifically designed for professional gel manicures.

* Power and Wattage: The wattage of your lamp influences curing time. Higher wattage lamps generally cure faster. Check OPI's recommendations for suitable wattage ranges. Insufficient power can result in incomplete curing.

Troubleshooting Curing Issues

* Insufficient Curing: If your OPI Gel feels sticky or soft after curing, the lamp may be too weak, the curing time too short, or the lamp's bulbs may be aging. Try increasing curing time or replacing bulbs. Always follow OPI's recommended curing times.

* Uneven Curing: This could be due to incorrect lamp placement, uneven application of the gel, or a faulty lamp. Ensure the lamp is positioned correctly and the gel is applied evenly.

Types of UV/LED Lamps for OPI Gel

* LED Lamps: These lamps offer faster curing times and use less energy compared to UV lamps. They're generally the preferred choice for salons and professionals.

* UV Lamps: While functional, UV lamps usually require longer curing times and may not be as efficient as LED lamps. However, some older systems rely on UV-only technology.

* Hybrid Lamps: These lamps combine UV and LED technology, offering a versatile option.

Ensuring Proper Curing for Professional Results

* Follow OPI Instructions: Always adhere to the specific curing time recommendations provided by OPI for each of their products. These are carefully designed to ensure complete polymerization.

* Regular Lamp Maintenance: Replace old or malfunctioning bulbs promptly. Regularly clean the lamp to ensure effective light transmission. A dirty lamp may reduce curing efficiency.

* Client Consultation: Discuss any potential issues clients may experience with curing and adjust accordingly, understanding client nail health variables.

Note: While many UV lamps can *cure* OPI gel, optimal results require using a lamp that meets OPI's specifications for wavelength and wattage. Refer to OPI's official website and product instructions for detailed information and best practices.

How does UV technology make your product stand out?

The 11th Beijing International Printing Technology Exhibition Concluded Successfully, Vtech.Co.,Ltd.Guangzhou Achieved Fruitful Results

Vtech water-cooled UV/LED system helps Roland 300 printing machine upgrade efficiency again!

Precision Cooling Solutions Power Global Printing Innovation: Vtech Shines at 2025 South China Printing Expo

Vtech showcases its innovative water-cooled UV/LED solution at the 2025 South China Printing Exhibition, helping to upgrade printing efficiency

How to choose the best UV light for resin

You may also like

Water cooled UV shutter lampshade

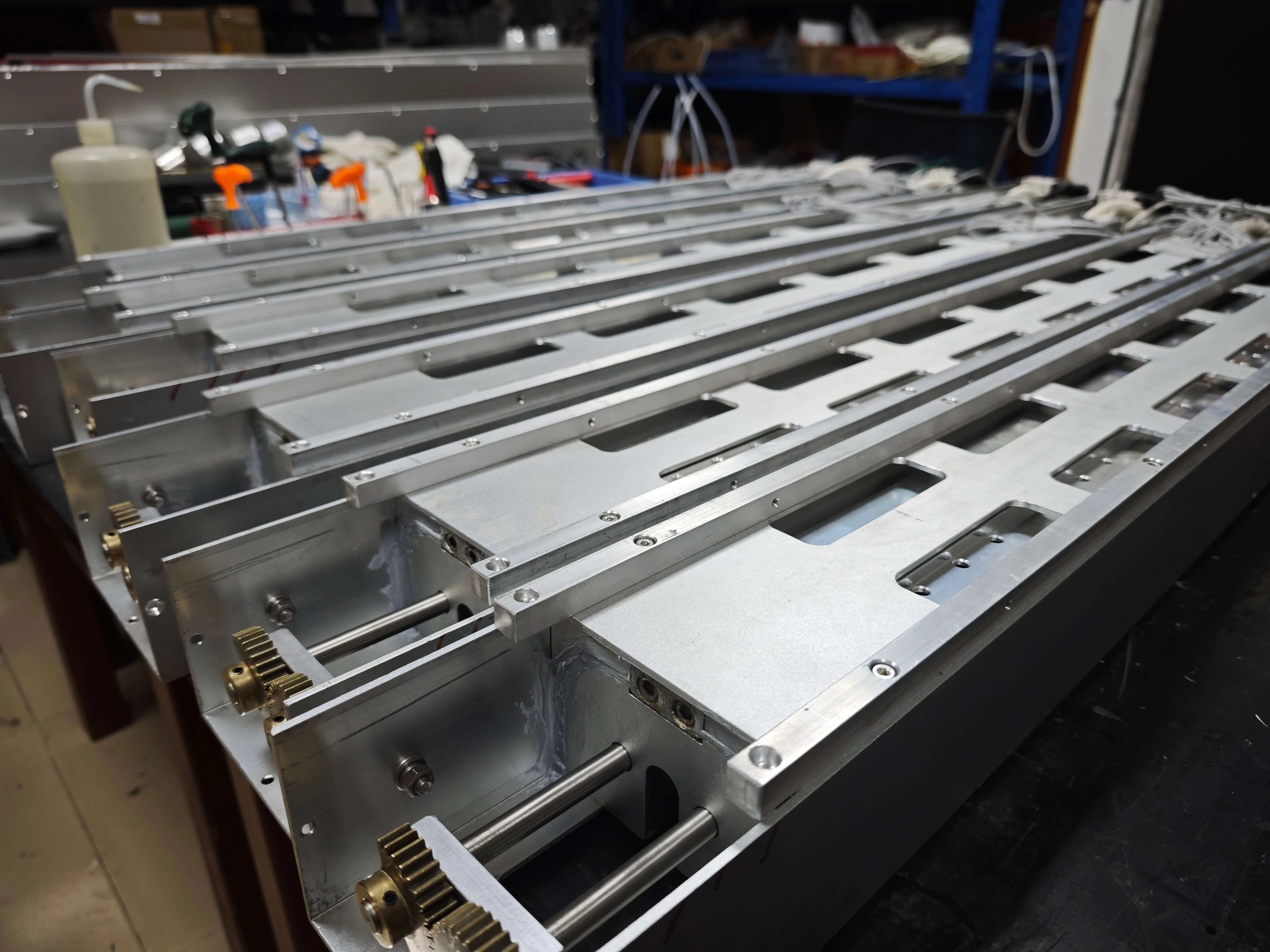

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

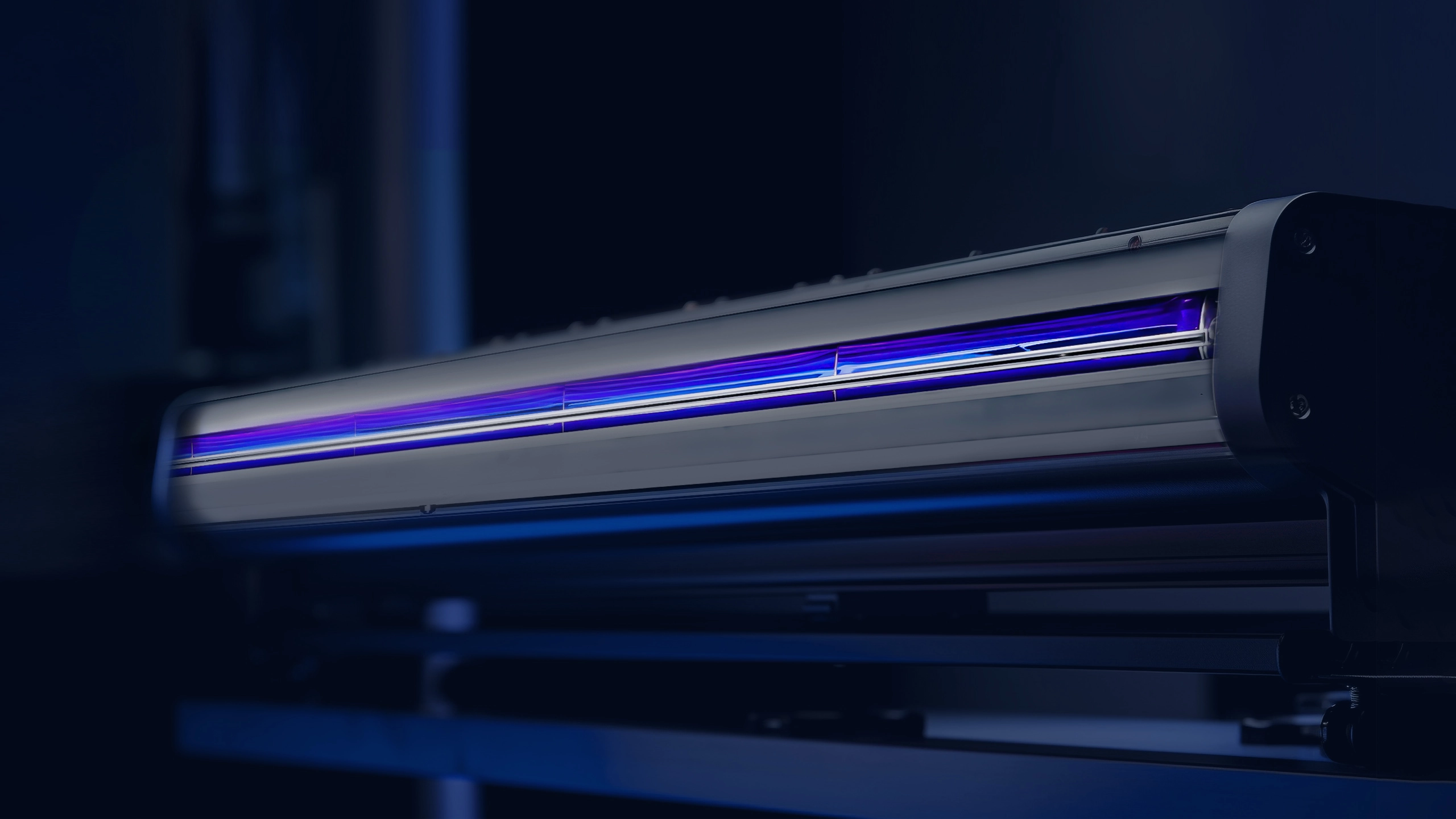

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

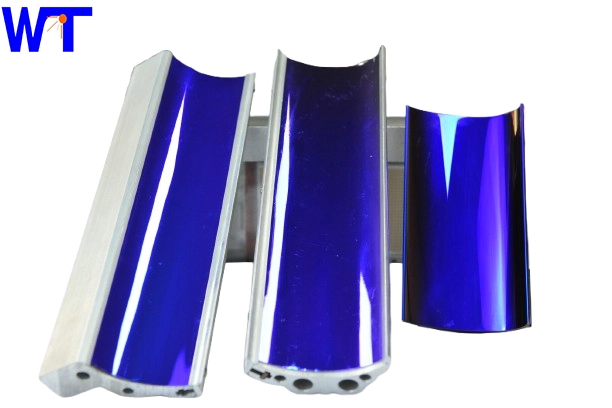

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Offset LED pre-press testing machine

Get in touch with us

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang