The Advantages of Utilizing a Benchtop UV Curing System

In recent years, benchtop UV curing systems have gained popularity in various industries due to their efficiency and effectiveness in curing different materials. This blog post will explore the benefits of using a benchtop UV curing system and how it can improve your production process.

Enhanced Curing Capabilities:

One of the major advantages of using a benchtop UV curing system is its enhanced curing capabilities. These systems are equipped with high-intensity UV lamps that provide uniform and consistent curing, resulting in faster processing times and improved product quality.

Flexible and Versatile:

Benchtop UV curing systems are designed to be flexible and versatile, making them suitable for a wide range of applications. Whether you are curing adhesives, coatings, or other materials, these systems can accommodate different curing requirements, making them a valuable asset in various industries.

Cost-Effective Solution:

Unlike traditional curing methods that require significant energy and time, benchtop UV curing systems offer a cost-effective solution for curing needs. These systems consume less energy and have a longer service life, reducing operational costs and increasing overall efficiency.

Compact and Space-Saving:

Another benefit of utilizing a benchtop UV curing system is its compact and space-saving design. These systems are typically small in size and can be easily integrated into existing production lines, making them ideal for facilities with limited space.

Environmentally Friendly:

UV curing systems emit minimal heat and do not produce harmful emissions, making them an environmentally friendly option for curing materials. By using UV light to cure products, you can reduce your carbon footprint and contribute to a more sustainable production process.

Improved Production Efficiency:

By incorporating a benchtop UV curing system into your production process, you can significantly improve efficiency and productivity. These systems enable faster curing times, reducing cycle times and increasing overall output, ultimately leading to improved profitability.

Conclusion:

In conclusion, the benefits of using a benchtop UV curing system are undeniable. From enhanced curing capabilities to cost-effective solutions, these systems offer a range of advantages that can greatly impact your production process. By investing in a benchtop UV curing system, you can achieve improved efficiency, product quality, and environmental sustainability.

The Ultimate Guide to UV Flood Curing Systems | Vtech Co., Ltd

The Ultimate Guide to Industrial UV Curing Systems by WT

What are the different types of cure uv?

The Ultimate Guide to UV Light Curing Systems for Industrial Use

normal

Where is your factory located?

How does your factory do the quality control?

Can you do a design for me or company?

What's the whole UV LED curing system including?

Can we visit the factory?

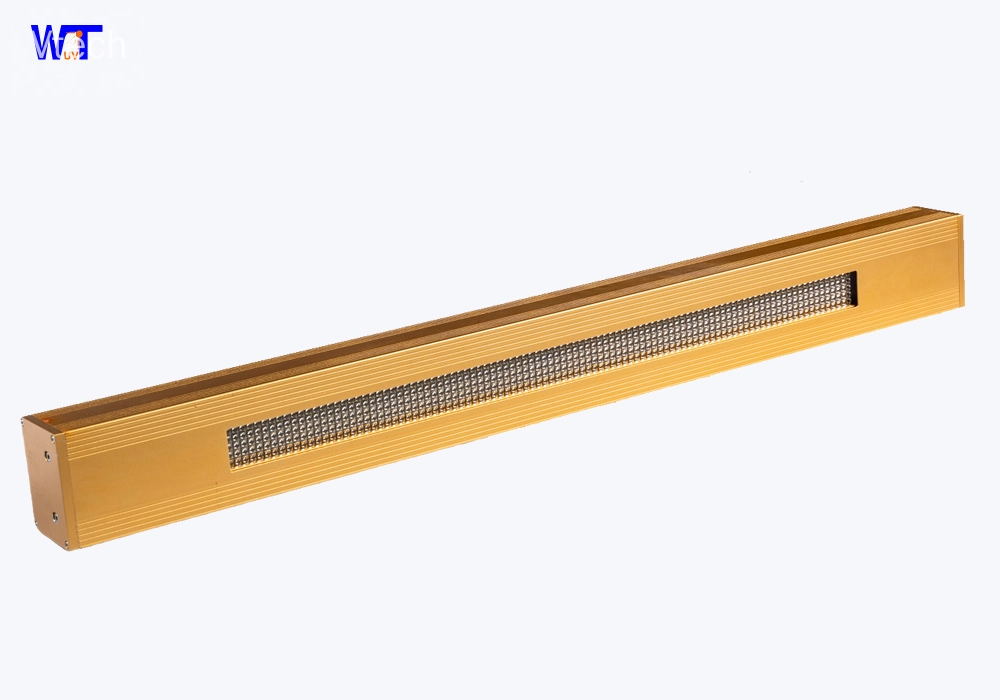

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang