WT UV Curing Light Systems: Superior Performance & Efficiency

Discover the power and precision of WT UV Curing Light Systems, designed to revolutionize your curing process with unmatched efficiency and accuracy. At WT, we recognize the importance of delivering reliable and consistent results, which is why our UV curing systems are engineered to meet the highest industry standards.

WT UV Curing Light Systems offer a sterling combination of advanced technology and user-friendly design, making it the ideal choice for professionals across various industries. Whether you're in printing, packaging, electronics, or automotive sectors, our systems ensure a quicker curing process, significantly reducing production time and enhancing product integrity.

Our systems feature cutting-edge UV LED technology, which operates with minimal heat emission. This innovation not only extends the lifespan of your equipment but also provides energy efficiency, making it an eco-friendly choice for your business. With precise controls and customizable settings, you can tailor the curing process to fit the unique requirements of your projects, ensuring optimal performance every time.

Clients using WT UV Curing Light Systems continually commend the superior quality output, which enhances their product's aesthetic and functional qualities. Moreover, the easy installation and maintenance of our systems mean less downtime and more productivity for your operations.

Choosing WT UV Curing Light Systems means choosing quality, reliability, and efficiency. Feel valued and supported with our exemplary customer service as you transition your business to the forefront of technology. Experience the WT difference—where innovation meets excellence, and your success is our mission.

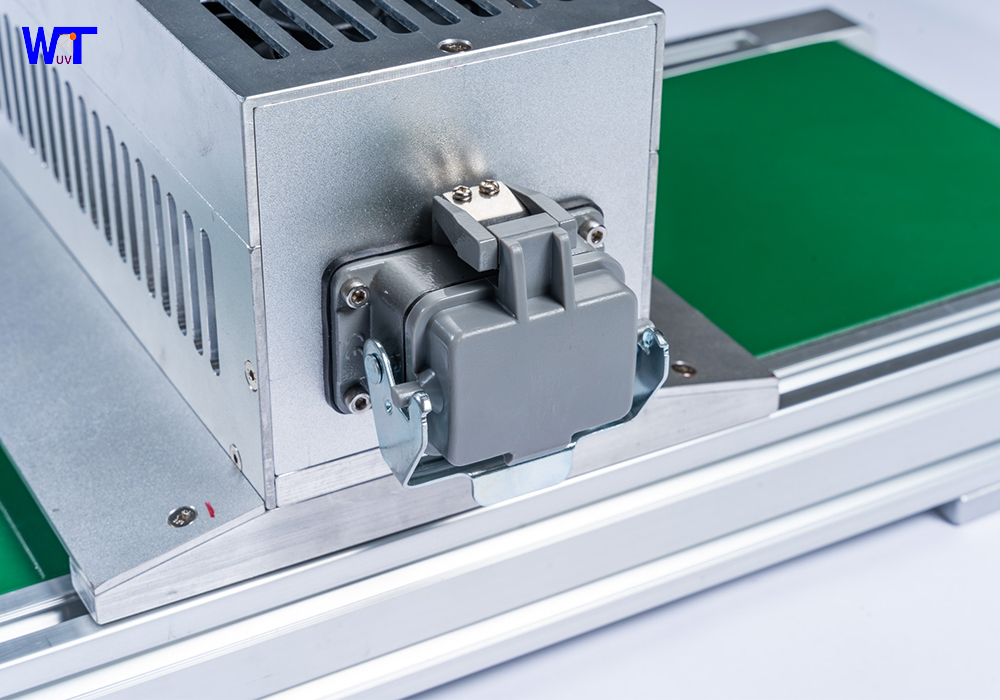

Product Images

Advantages

Compact size, making it easy to integrate into fully automated production lines and equipment.

The operation interface is simple, the sound and light alarm corresponds to the light source module, and the fault can be quickly determined.

With line disconnection alarm and LED dead point detection alarm function.

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

FAQ

What is the major advantages of UV LED curing system’s than other UV curing system?

Where is your factory located?

Why choose Vtech's UV LED curing machine?

Can we visit the factory?

Water-cooled LED curing equipment

Small UV drying machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang