WT High Power UV LED Curing System: Speed & Efficiency

Experience unparalleled efficiency and precision with the WT High Power UV LED Curing System. Designed for industrial-grade performance, this cutting-edge solution is engineered to meet the rigorous demands of today’s manufacturing and printing industries. The WT UV LED Curing System offers superior curing speeds and energy efficiency, making it the ideal choice for businesses looking to enhance productivity and reduce operational costs.

What sets the WT system apart is its high power output, delivering intense UV energy that ensures rapid curing of inks, adhesives, and coatings. This advanced technology not only guarantees a flawless finish but also significantly reduces downtime, enhancing overall workflow efficiency. With an extended lifespan and reduced heat emission, it also contributes to a safer and eco-friendlier working environment.

The user-friendly interface of the WT High Power UV LED Curing System simplifies operations, enabling seamless integration into existing production lines. Its compact design ensures a perfect fit, even in constrained spaces, providing flexibility without compromising on performance. Additionally, the system’s robust construction ensures durability and low maintenance requirements, translating to long-term cost savings.

Choose the WT High Power UV LED Curing System to revolutionize your production capabilities. Embrace a solution that combines high power, efficiency, and sustainability, setting your business on a path to greater innovation and growth.

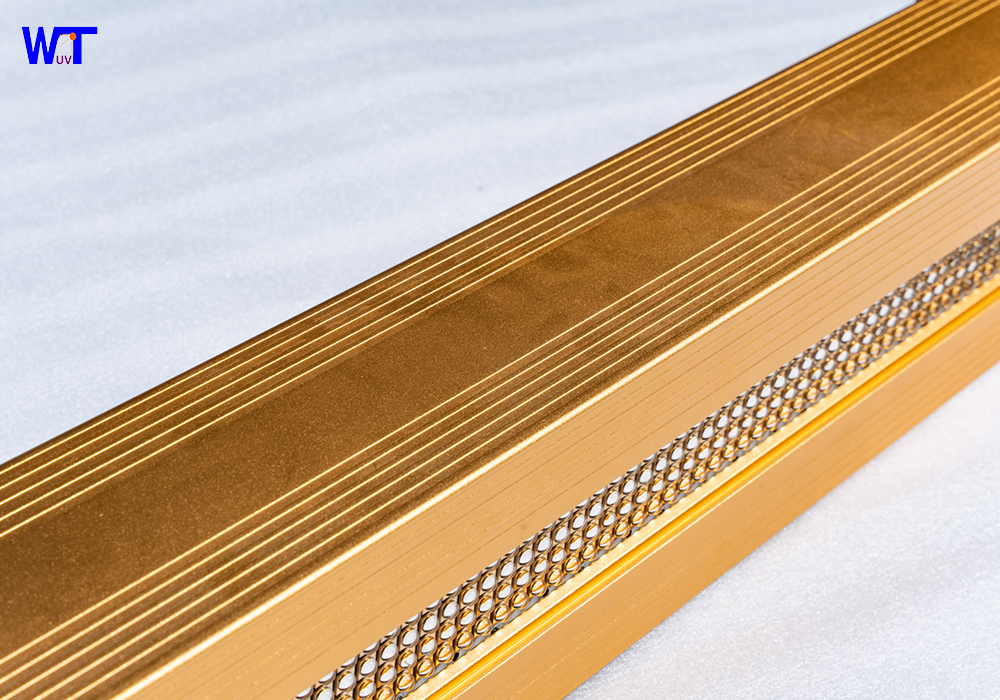

Picture Show

Our Advantages

Compact size, making it easy to integrate into fully automated production lines and equipment.

Can be designed and customized development, a variety of optical wavelength optional.

The light source head adopts a modular design.

UV energy uniformity ≥ 98%.

Q&A

Why and how do I replace a UV led?

What's the Peak Irradiance do I need?

How long will take for mass production?

Where is your factory located?

If you have any other questions, please write email to us or call us , we will reply you ASAP.

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang