WT edale fl1 prime LED UV Curing System: Precision, Efficiency, Sustainability

Are you seeking to elevate your production process with advanced curing technology? The WT edale fl1 prime LED UV Curing System by Vtech Co., Ltd is engineered to deliver unparalleled performance, bringing precision, efficiency, and sustainability to your operations.

Backed by Vtech Co., Ltd's nearly two decades of innovation since 2006, our commitment to research and development has resulted in numerous industry patents. We specialize in cutting-edge water-cooled and LED UV curing systems, trusted across a diverse range of applications, including offset, gravure, flexo press, coatings, and silk screen print. With WT, you’re investing in proven expertise and reliable, high-efficiency production solutions.

Unlocking Peak Performance with edale fl1 prime

The edale fl1 prime system isn't just a component; it's a strategic upgrade designed to transform your workflow. Experience a new benchmark in curing speed and quality, reducing bottlenecks and enhancing your output with every run.

Superior LED UV Technology

At the heart of the edale fl1 prime is state-of-the-art LED UV technology. Unlike traditional UV methods, our system offers instant ON/OFF functionality, virtually eliminating warm-up times and standby energy consumption. This translates to significant energy savings and a drastically reduced carbon footprint. Expect longer lamp life, minimal heat emission, and no ozone production, creating a safer, more sustainable working environment. Achieve uniform, consistent cures on a wider range of substrates, including heat-sensitive materials, without compromise.

Designed for Diverse Applications

Whether your focus is high-speed flexo, precision gravure, vibrant offset printing, protective coatings, or intricate silk screen applications, the edale fl1 prime is engineered for versatility. Its robust design and adaptable configurations ensure seamless integration into your existing production lines, providing reliable, efficient curing that meets the demanding requirements of various industries. Boost your productivity, cut operational costs, and deliver superior product quality consistently.

Why Choose WT (Vtech Co., Ltd)?

Choosing WT means partnering with a leader in UV and LED curing solutions. Our extensive experience and expertise allow us to provide tailor-made systems that address your unique production challenges. We stand by our commitment to innovation, quality, and customer satisfaction, ensuring you receive a system that not only performs but also adds lasting value to your business. Let us empower your production with technology you can trust.

Product Image

Advantages

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

The operation interface is simple, the sound and light alarm corresponds to the light source module, and the fault can be quickly determined.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

LEDs do not produce ozone gas.

Q&A

Are you a trader or manufacturer?

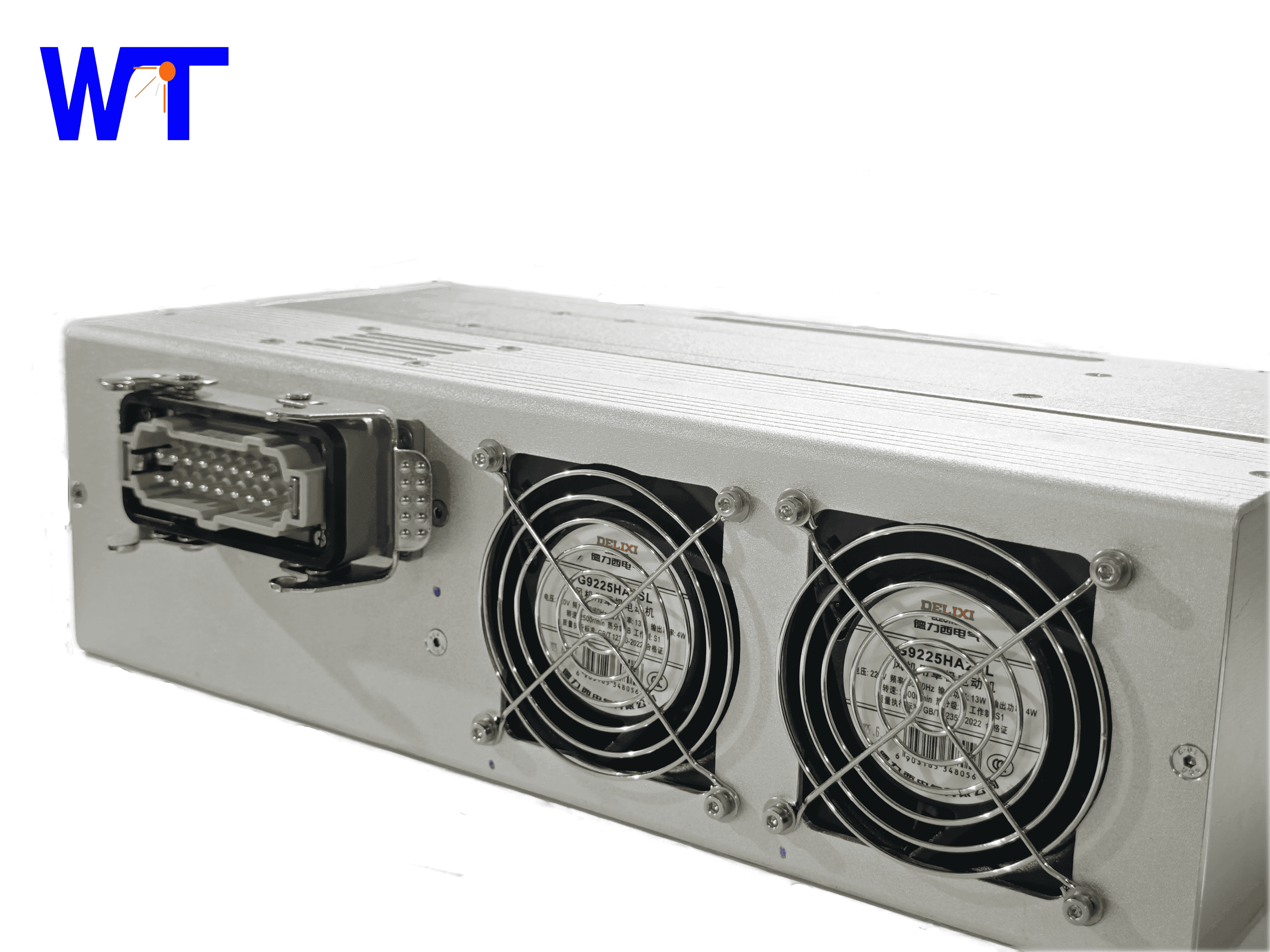

What's the cooling way?

Why and how do I replace a UV led?

How about the after service?

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

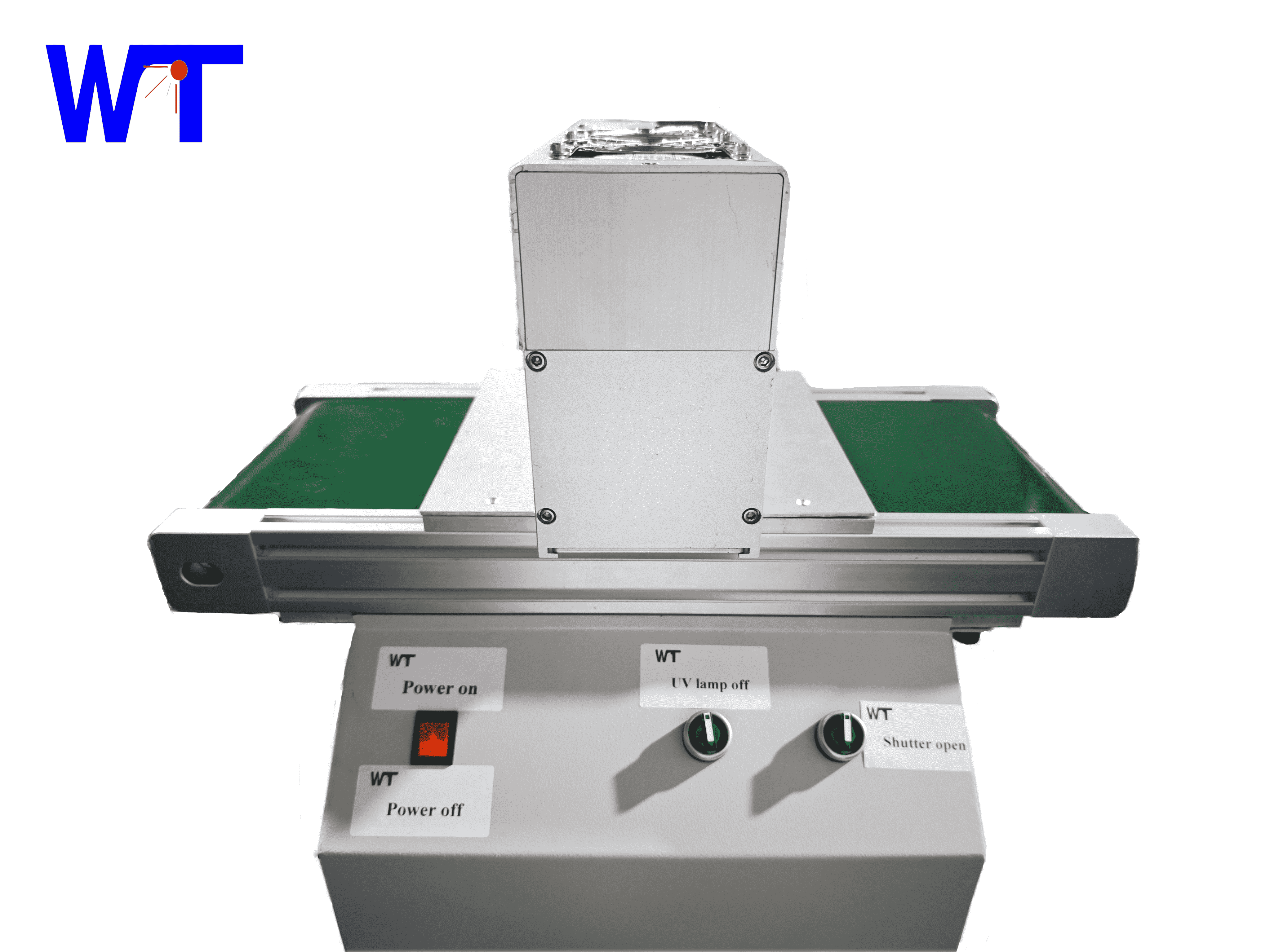

Small UV drying machine

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

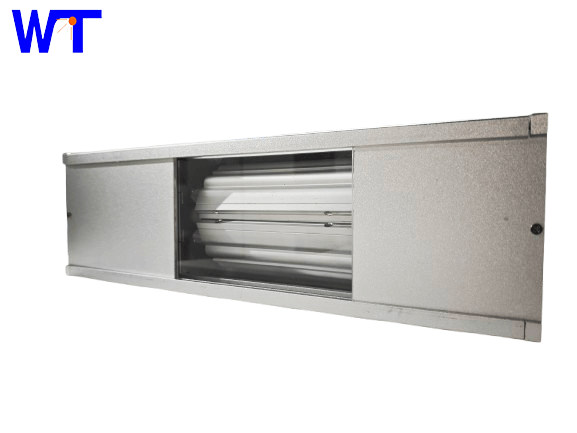

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Customized conveyor belt type UV LED curing equipment

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang