WT Bobst UV Curing Systems: Precision & Performance for High-Speed Printing

WT Bobst UV Curing Systems: Precision & Performance for High-Speed Printing

In the fast-paced world of industrial printing and coatings, efficiency, reliability, and exceptional finish are paramount. The WT Bobst UV Curing System, proudly engineered by Vtech Co., Ltd., stands as a beacon of innovation and performance, specifically designed to meet the rigorous demands of high-performance presses, including Bobst machinery.

Since 2006, Vtech Co., Ltd. has specialized in cutting-edge UV and LED UV curing technologies. Our extensive experience, numerous industry patents, and dedicated R&D have culminated in a product line that guarantees superior results. The WT Bobst UV Curing System brings this legacy of excellence directly to your production line, ensuring your output is not just good, but exceptional.

Why Choose WT Bobst UV Curing Systems?

Precision & Performance for Demanding Applications

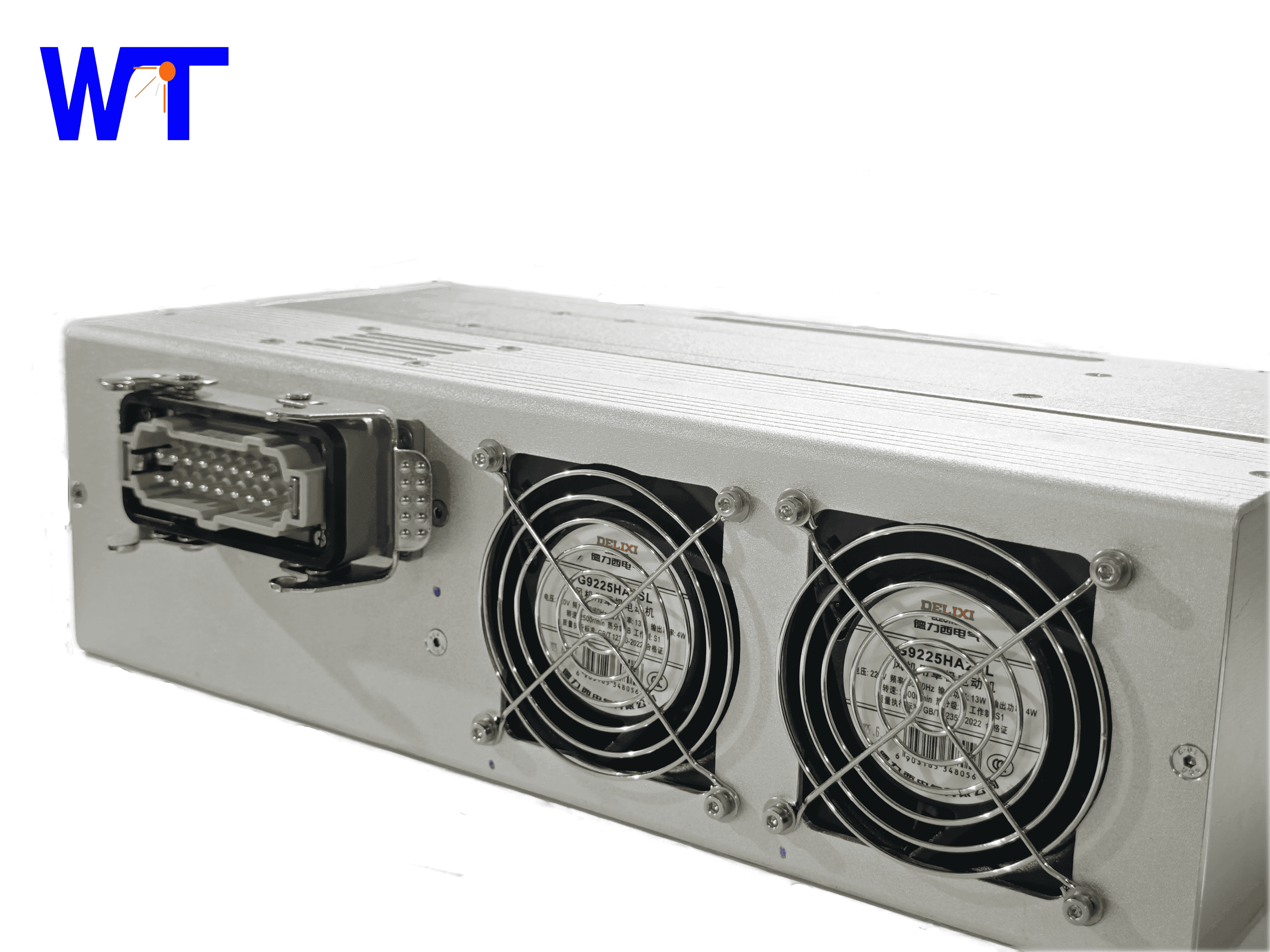

Our WT UV curing systems are meticulously engineered to deliver consistent, high-quality curing. Featuring advanced water-cooled technology, they maintain optimal operating temperatures, ensuring stability and extending the lifespan of components. This precision is vital for applications requiring flawless finishes on offset, gravure, flexo, and screen printing, as well as various coating processes. Experience rapid cure times that boost your throughput without compromising on quality.

Unmatched Reliability & Efficiency

Reliability is at the core of every WT system. Vtech's robust design and manufacturing ensure minimal downtime, allowing your operations to run smoothly and efficiently. The WT Bobst UV Curing System provides consistent energy output, leading to uniform curing across the entire substrate, reducing waste, and maximizing your operational cost-effectiveness. Trust in a system built for continuous, high-volume production.

Vtech's Expertise & Innovation Behind Every System

With Vtech, you're investing in more than just a product; you're gaining a partner with profound industry expertise. Our track record of developing patented, high-performance UV and LED UV curing solutions for diverse industrial needs speaks for itself. We understand the nuances of various printing techniques and offer tailored systems that integrate seamlessly into your existing Bobst setup, providing you with peace of mind and a significant competitive edge.

Applications & Versatility

Tailored for Diverse Printing Needs

Whether you're working with intricate labels, flexible packaging, or high-definition graphics, the WT Bobst UV Curing System delivers. Its adaptable nature makes it ideal for a broad spectrum of materials and inks, ensuring vibrant colors, superior adhesion, and enhanced durability. Elevate your product quality and broaden your service offerings with a versatile curing solution from Vtech.

Choose WT Bobst UV Curing Systems for a future of enhanced productivity, impeccable quality, and unwavering reliability. Contact Vtech Co., Ltd. today to discover how our expertise can transform your curing process.

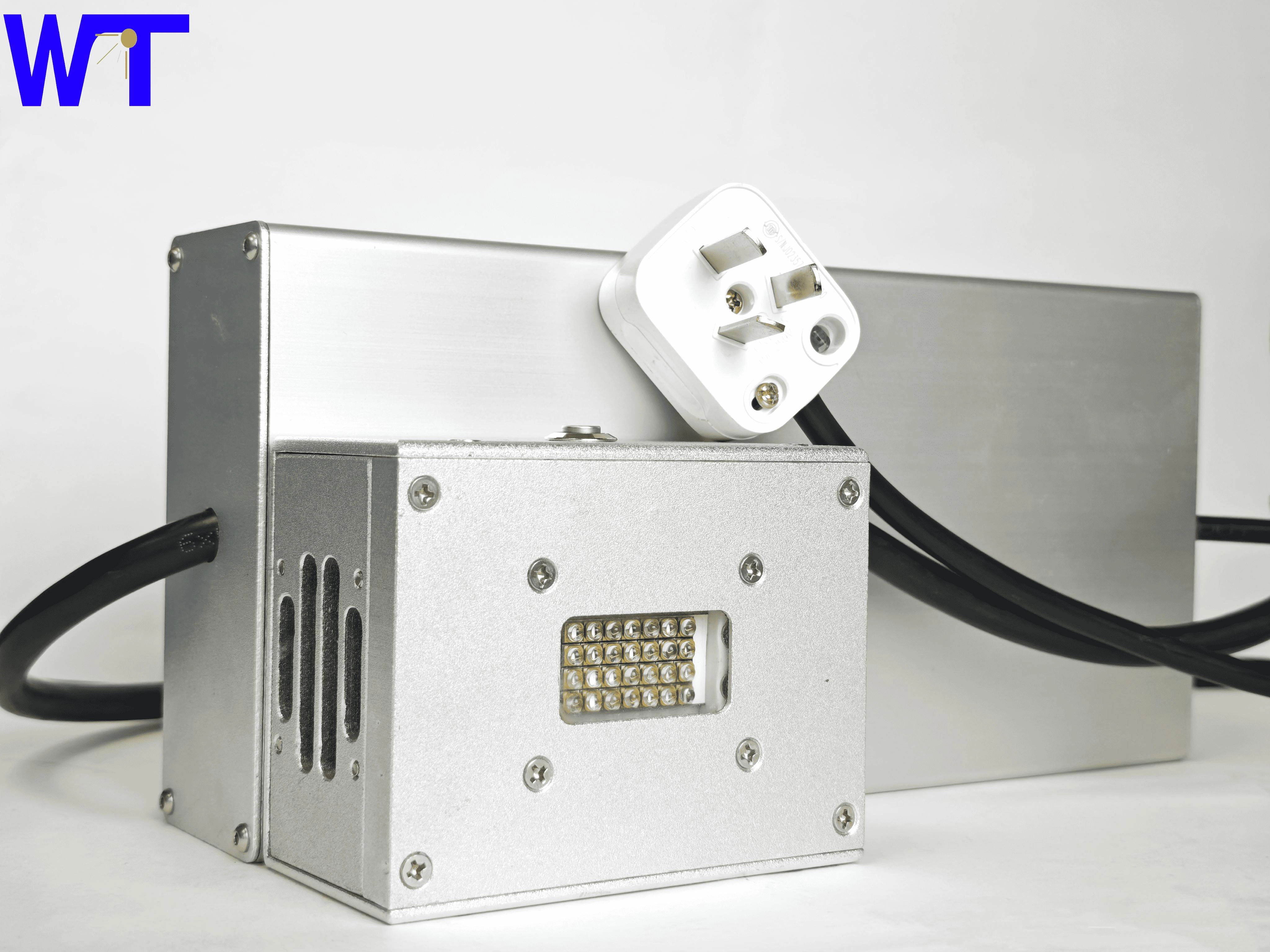

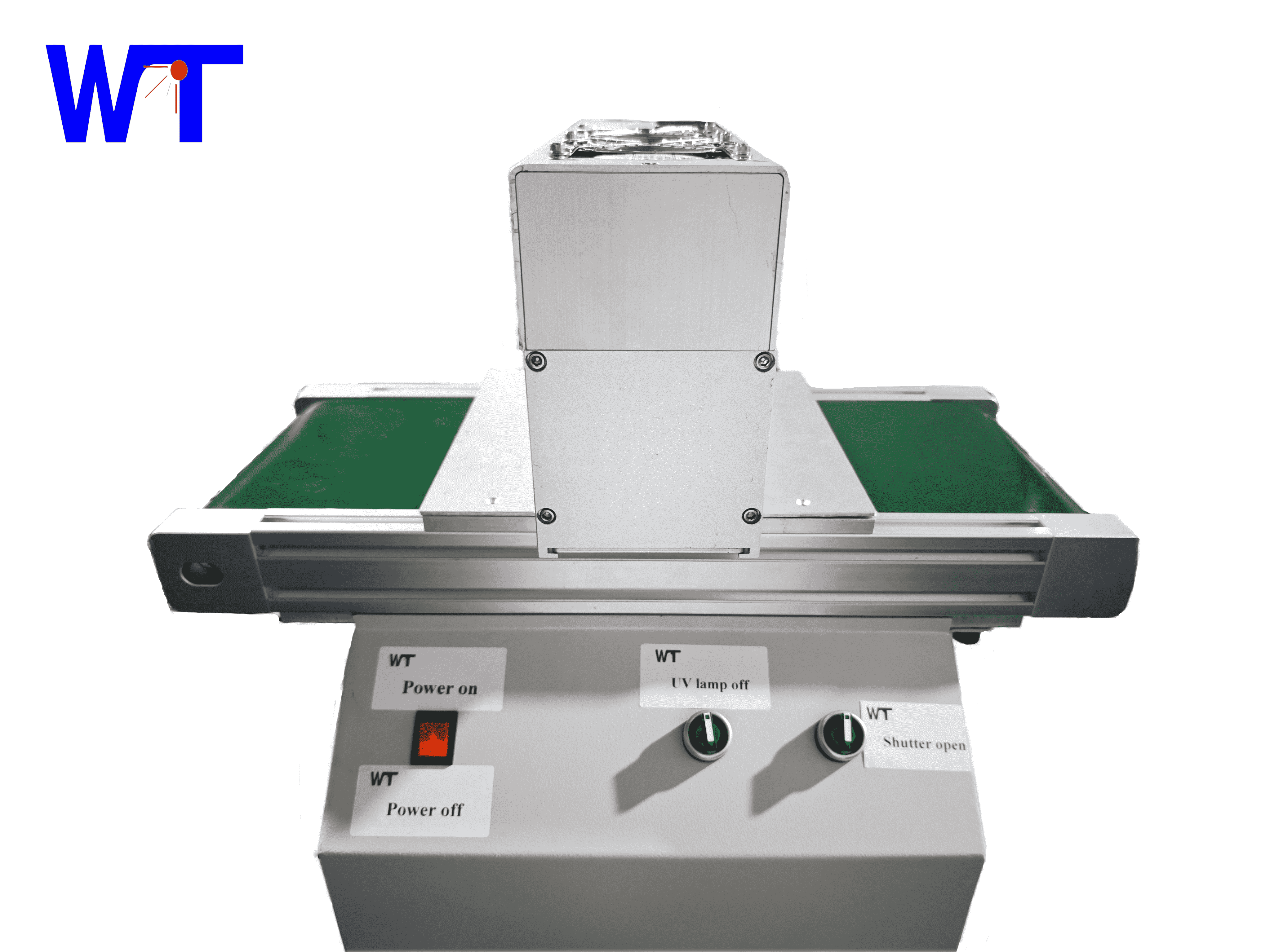

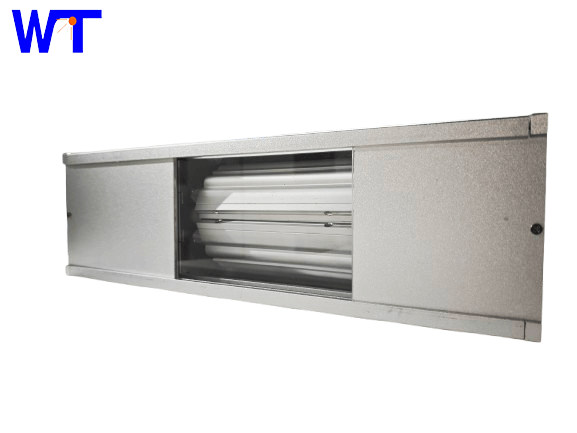

Detailed display

Our Advantages

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

24 Hours Service Hotline: All our team of service are fully conversant with our extensive range of products and can quickly and expertly talk you through any question you may ask. Vtech is committed to provide a 24 hours customer service/breakdown hotline in local office.

It adopts special military-grade UVLED constant current power supply, which has intact short circuit protection, leakage protection, overcurrent and overvoltage protection, and undervoltage protection.

Q&A

Where is your factory located?

Why and how do I replace a UV led?

What materials can UV printers print?

What is the major advantages of UV LED curing system’s than other UV curing system?

If you have any questions or concern, please contact us.

Small UV drying machine

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Customized conveyor belt type UV LED curing equipment

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang