WT Bobst Printing Press UV Curing System

Product Overview

The WT Bobst Printing Press UV Curing System is specially designed to work with Bobst presses, offering water-cooled UV and LED curing options for a wide range of printing applications. Produced by Vtech Co., Ltd—established in 2006 and backed by multiple industry patents—this system brings reliable curing performance, stable production, and professional service to your shop.

Key Features

Compatibility: Seamless integration with Bobst offset, flexo, and other presses to minimize downtime during installation.

Efficient Cooling: Advanced water-cooled design ensures consistent temperature control for stable lamp performance and longer component life.

LED Option: Available LED UV modules for lower energy consumption, reduced heat, and longer lamp lifetime.

Fast Curing: High-intensity output delivers quick curing speeds that improve throughput and reduce production bottlenecks.

Simple Operation: User-friendly controls and clear status indicators make daily operation easy for any press operator.

Benefits

Choosing the WT system means investing in predictable, higher-quality print results and more efficient production. Faster curing reduces set-up time and waste, while stable cooling and durable components cut maintenance costs. Vtech’s experience and patent-backed designs ensure you receive a well-engineered solution supported by responsive technical service.

Who Should Choose This System

This curing system is ideal for print shops using Bobst equipment that want to increase speed, improve print quality, and lower operating costs. It suits applications including coatings, varnishes, packaging, and high-speed label runs.

Support and Service

Vtech Co., Ltd provides full technical support, installation guidance, and spare parts. Our team has deep experience in UV and LED curing—ensuring fast response and reliable after-sales care so you feel supported at every step.

Contact us today to learn how the WT Bobst UV Curing System can improve your press performance and productivity.

Product Image

Our Advantages

With line disconnection alarm and LED dead point detection alarm function.

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

We are the source factory with professional R&D team and skilled workers.

Limmediately on and off without preheating. The irradiation intensity can reach 500mw/cm2-- 12000mw/cm2 or higher.

Q&A

how can we guarantee quality?

Why and how do I replace a UV led?

What should I do when I don’t really know how to setting the printer parameters?

Where is your factory located?

If you have any questions about our goods or services, please feel free to contact us.

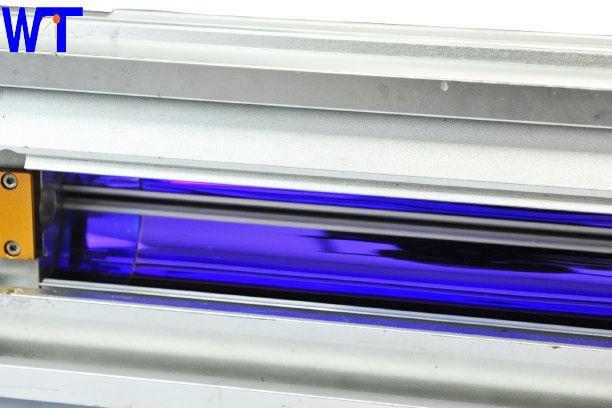

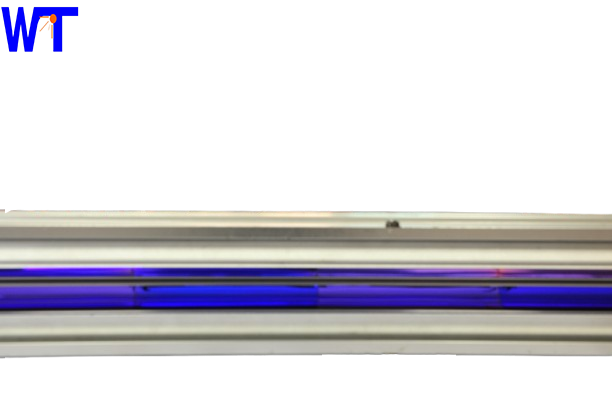

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

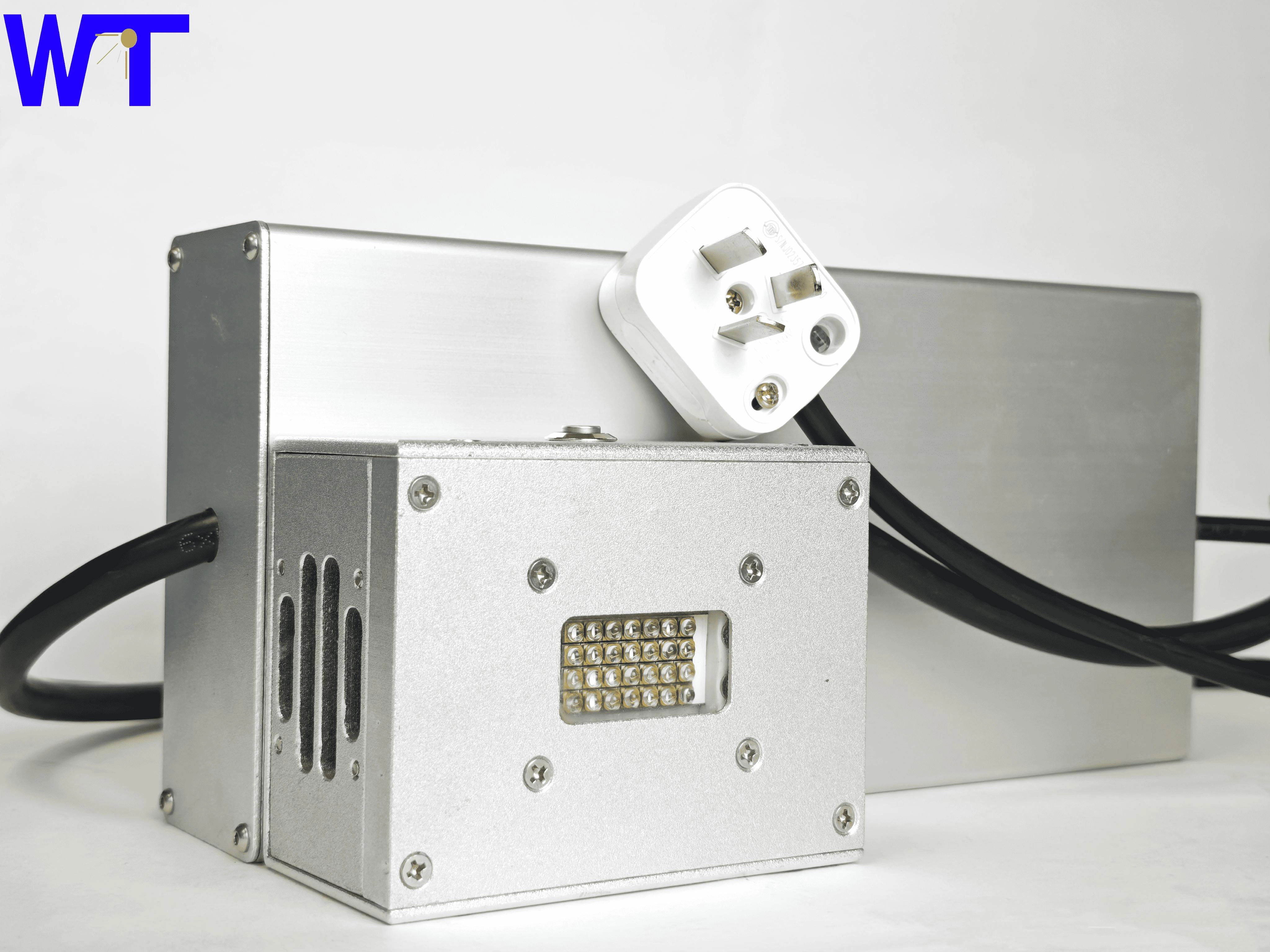

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang