WT UV LED Curing Area System

Product Overview

The WT UV LED Curing Area System is a reliable solution designed to deliver consistent, high-speed curing for printing and coating lines. Built by Vtech Co., Ltd (est. 2006), a specialist in water-cooled and LED UV systems with multiple industry patents, this system combines efficient LED technology with practical engineering to improve production quality and uptime.

Key Features

- Wide curing area: covers large web and substrate widths for offset, flexo, gravure and screen printing.

- Water-cooled design: maintains stable temperature for long LED life and consistent curing.

- Adjustable intensity: precise control over cure strength for different inks and coatings.

- Energy-efficient LEDs: lower power use and reduced maintenance compared with traditional lamps.

- Modular and compact: easy to integrate into existing production lines.

- Safety features: enclosed design and interlocks to protect operators.

Benefits

Increase throughput and reduce rejects with uniform, fast curing. The WT system shortens drying times, improves ink adhesion and surface finish, and lowers operational costs thanks to long-lasting LEDs and efficient cooling. Its easy controls help operators set up quickly, reducing downtime and training needs.

Why Choose WT & Vtech

Vtech Co., Ltd has focused on UV curing solutions since 2006, supplying systems for offset press, gravure, flexo press, coatings and silk screen print. With patented designs and experienced technical service, WT products offer dependable performance and responsive after-sales support. Choosing WT means a partner who understands production challenges and delivers practical, durable solutions.

Applications and Integration

The WT UV LED Curing Area System is ideal for commercial and industrial environments: sheetfed and web offset, flexographic packaging, gravure labels, industrial coatings and textile printing. Its modular form factor allows straightforward mounting, retrofitting or full-line installation with minimal disruption.

Technical Support

We provide installation guidance, maintenance tips and prompt technical service. Contact Vtech for customized configurations, spare parts and training to maximize your system’s value.

Contact us to learn how the WT UV LED Curing Area System can increase your production efficiency and quality.

Product Image

Our Advantages

UV energy uniformity ≥ 98%.

LEDs do not produce ozone gas.

With line disconnection alarm and LED dead point detection alarm function.

The light source head adopts a modular design.

Frequently Asked Questions

Can you do a design for me or company?

Why and how do I replace a UV led?

Are you a trader or manufacturer?

how can we guarantee quality?

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

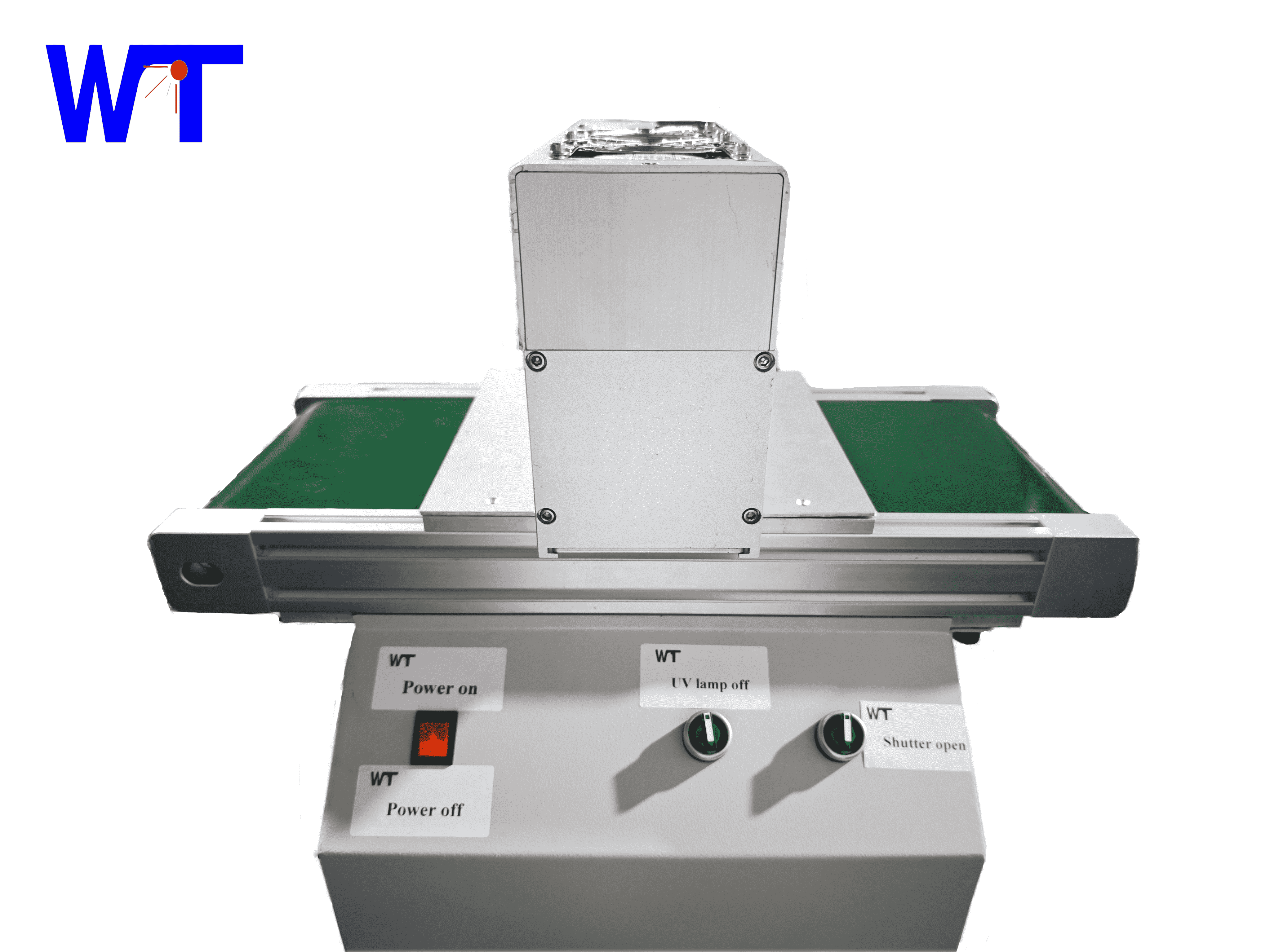

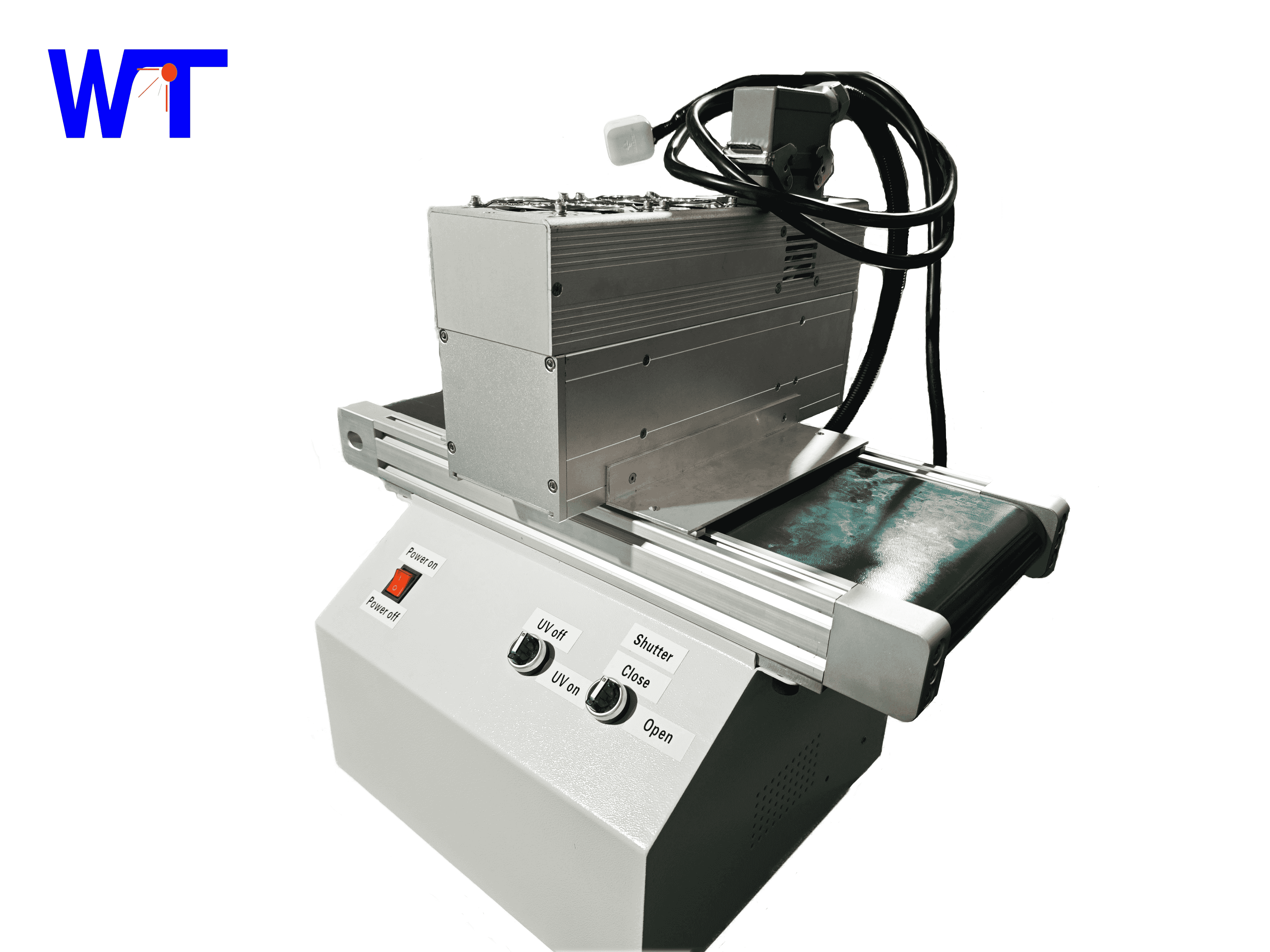

Small UV drying machine

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Small UV drying machine

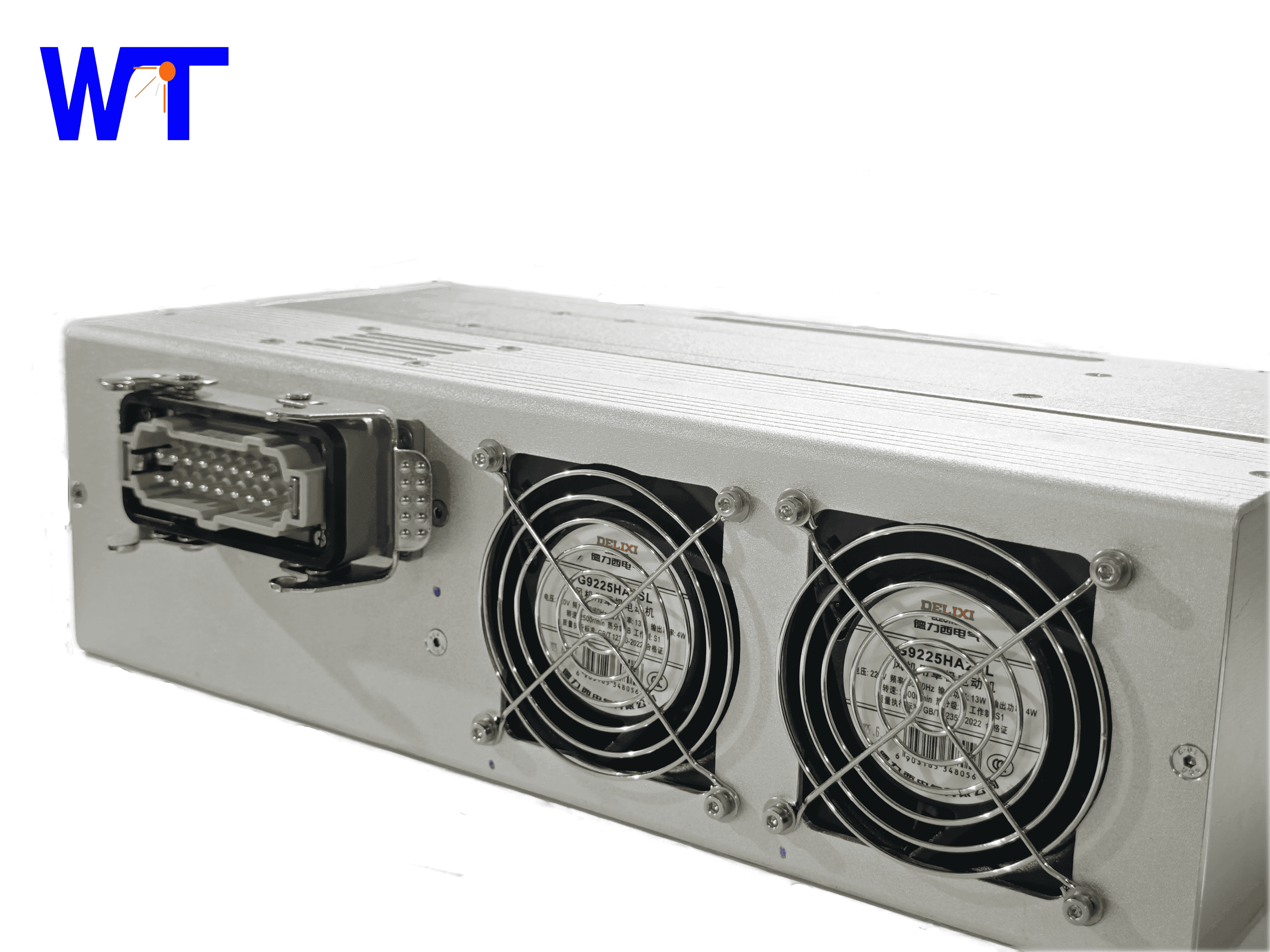

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang