WT UV Glue Curing Systems | Superior Bonding

WT UV Glue Curing Systems: Superior Bonding Solutions

WT offers a range of high-performance UV glue curing systems designed for precision and reliability. Whether you need a handheld unit for small-scale applications or a robust industrial system for high-volume production, our solutions deliver consistent, rapid curing for a wide variety of UV adhesives.

Our systems utilize cutting-edge technology, ensuring optimal curing times and superior bond strength. We prioritize user-friendliness, incorporating intuitive controls and ergonomic designs for seamless operation. Every WT system undergoes rigorous quality control testing to guarantee consistent performance and long-term durability.

From electronics assembly to medical device manufacturing, our UV glue curing systems offer the speed, efficiency, and reliability your business demands. Choose WT for superior bonding results and peace of mind. Explore our full range of systems and find the perfect solution for your needs. Contact us today for expert advice and a personalized consultation.

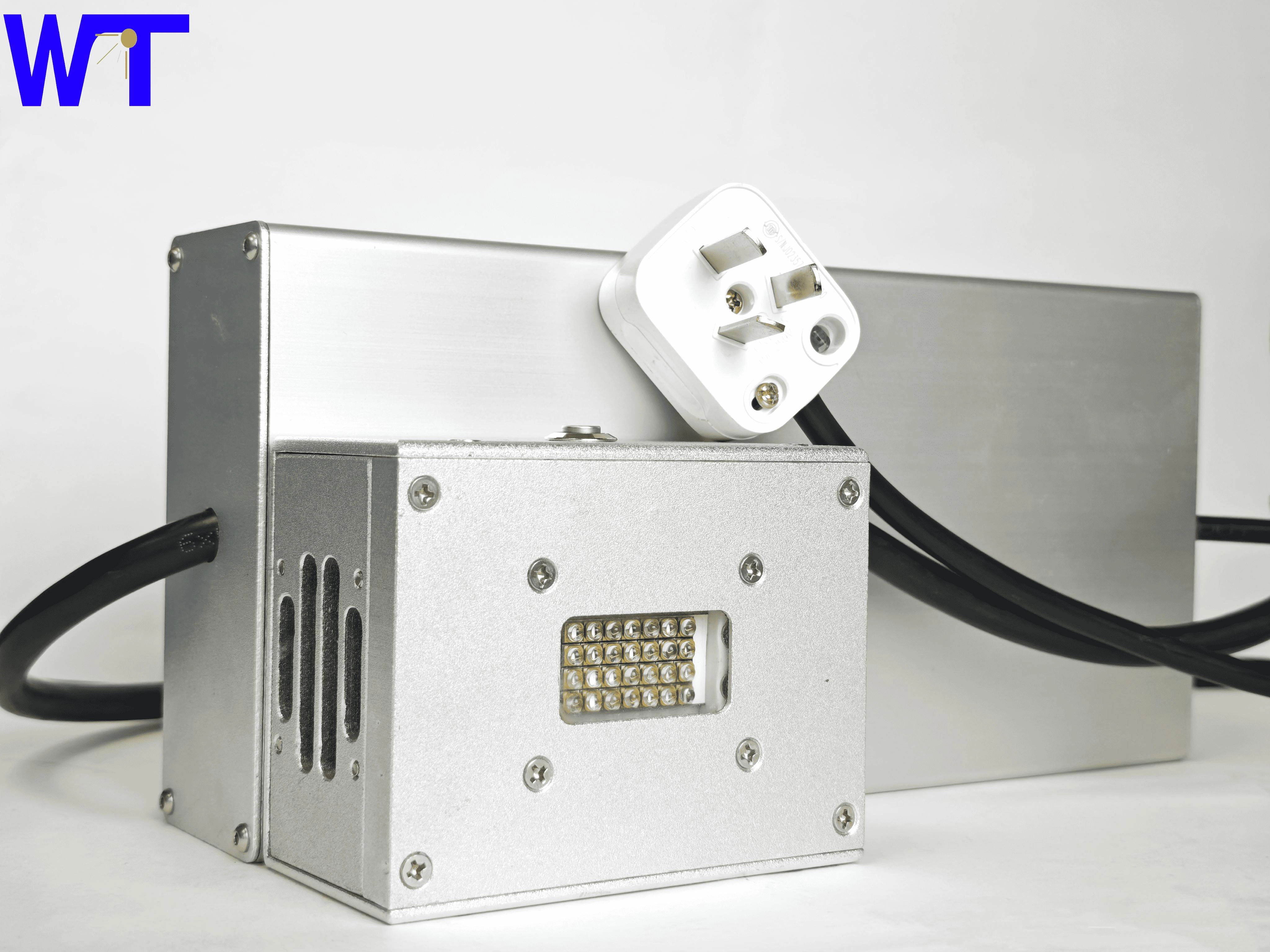

Detailed display

Our Advantages

UV energy uniformity ≥ 98%.

The operation interface is simple, the sound and light alarm corresponds to the light source module, and the fault can be quickly determined.

1. The conveyor speed can adjustment according to the products drying condition;

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

Q&A

Why and how do I replace a UV led?

Where is your factory located?

lf the light intensity is adjustable?

How to cooperate with you and what is the cooperation process?

If you have any other questions, please write email to us or call us , we will reply you ASAP.

Customized conveyor belt type UV LED curing equipment

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang